In the early morning at the port, cargo ships stall with unstarted diesel engines, delaying shipments. In remote rescues, diesel engines break down, risking missed rescue windows. During military tasks, failed diesel equipment hurts efficiency and safety—these are common industry issues.

Beyond “temporary downtime,” delays bring demurrage or breach claims; idle gear extends construction timelines and loses money. Emergencies may endanger trapped people, while mines/oil fields face secondary accidents. Repairs add costs, leaving a dilemma. This article breaks 4 core causes of diesel engine startup failures to help you pinpoint issues, resolve faults quickly, and minimize startup failures at the source.

Part 1. Faulty or Incompatible Starter Systems

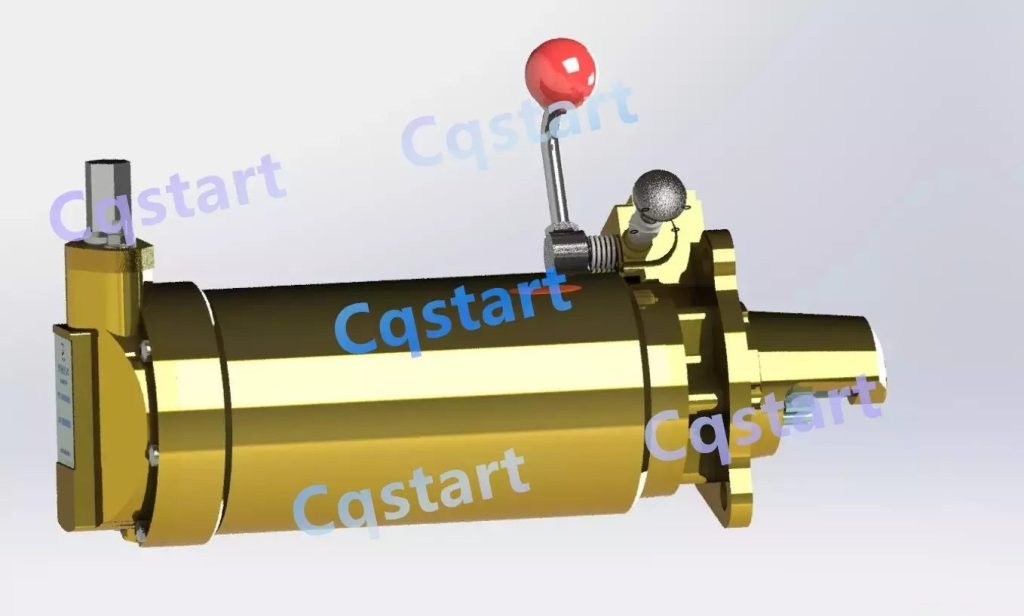

The starter system is the “first gate” for diesel engine ignition. As its core component, a spring starter will directly cause startup failure if it malfunctions or is incompatible with the engine.

(1) Incorrect Displacement Matching

A spring starter’s displacement must strictly match the engine’s—this is the basis for ensuring startup efficiency. Many users overlook this key parameter when selecting a model, leading to faults. For example, a port ship with an 8L engine was incorrectly fitted with a Cqstart Series 1 spring starter (designed for 4-7L engines), which couldn’t provide enough power. In use, the starter ran repeatedly but failed to turn the engine crankshaft, even overheating after multiple attempts.

This mismatch is essentially a “small horse pulling a big cart” power imbalance. A starter with insufficient displacement can’t meet the needs of a large-displacement engine, causing failure and accelerating internal wear.

(2) 3 Typical Signs of Starter Failure

- Unusual Noises: Metal scraping (“clatter”) or idle humming during startup indicates gear misalignment or energy storage component faults.

- Failure to Engage Within 30 Seconds: If the starter doesn’t mesh with the engine flywheel within 30 seconds, its transmission mechanism is likely stuck.

- Intermittent Failure: Irregular startup success suggests poor internal wiring or aging spring components. Stop use immediately if these signs appear.

(3) Solution: Choose Cqstart Spring Starters by Displacement

Cqstart offers clear product series for different displacements:

- 4-7L engines: Series 1 (stable torque for small/medium engines).

- 7-10L engines: Series 2 (enhanced energy storage for large engines).

- 13-16L engines: Series 3 or custom models (for heavy equipment like mining/marine machinery).

Part 2. Environmental Damage to Starters

Diesel engines are often used outdoors in harsh conditions. Extreme temperatures, high humidity, and salt spray erode starters over time, damaging internal structures and leading to startup failure.

(1) 4 Common Environmental Threats

There are four common environmental threats. Extreme temperatures harm starters in two ways: summer heat over 60℃ ages internal rubber parts and reduces sealing, while sub-zero winters (especially northern regions) solidify lubricant, increasing mechanical resistance or jamming. Water immersion and humidity cause internal rust on starters used on ship decks, docks, or rainy construction sites. Oil contamination lowers transmission efficiency as diesel or lubricating oil sticks to gears and springs of construction/oilfield starters. Salt spray erodes coastal/marine equipment, causing electrochemical corrosion that even damages stainless steel.

(2) Why Environmental Damage Causes Failure

Environmental damage to starters happens gradually. Rust forms uneven oxide layers on metal parts, which leads to gear jamming. Aging rubber seals allow more water and oil to enter, worsening existing issues. Solidified or diluted lubricant increases friction, stopping the starter from reaching rated speed.

Environmental damage to starters is gradual. Rust creates uneven oxide layers on metal, jamming gears; aging rubber seals let in more water and oil, worsening issues; solidified or diluted lubricant raises friction, stopping the starter from reaching rated speed.

(3) Solution: Cqstart Weather-Resistant Spring Starters

Cqstart’s weather-resistant spring starters solve this. They have IP67 waterproof/oilproof design with oil-resistant seals, rubber parts tolerating -40℃ to 80℃, and low-temperature lubricant for all seasons. Their double anti-corrosion (galvanization + spray coating) works over 5 years in coastal areas (per salt spray tests).

Part 3. Improper Installation & Operation

Many users ignore starter installation standards and operating procedures, thinking “as long as it fits and turns, it’s fine.” However, incorrect installation and operation directly cause startup failure and may even damage the starter and engine.

(1) Two Common Installation Mistakes

Incorrect SAE screw fastening requires SAE – standard screws and 25-30N・m torque. Using non – standard screws or over – tightening deforms the starter shell; loose screws cause vibration and misalignment. Misalignment of drive axes leads to uneven gear wear. One team’s misaligned starter needed full replacement after 3 uses.

(2) Three Frequent Operation Errors

Over – operation (over 30 seconds) overheats the motor. Some users press the button for over 1 minute, burning the motor. Skipping pre – engagement (gears first, then motor) hits gears and flywheels. Frequent starts without 2-3 minute cooling shortens the starter’s life.

(3) Solution: Follow Cqstart’s Design & Guide

Cqstart optimizes for ease. Its starters have alignment marks and unique screw holes. Small models (4-7L engines) install in 10 seconds. They have 30 – second auto – power – off and clear operation guides, enabling correct use even by non – professionals.

Part 4. Lack of Maintenance or Poor-Quality Starters

Many users prioritize usage over maintenance, and choosing low-quality starters creates hidden failure risks. These two issues together significantly increase the probability of startup failure.

(1) Two Common Maintenance Gaps

Neglecting corrosion checks: Users rarely inspect the starter’s exterior and internal corrosion regularly. Only when startup fails do they find rusted gears or oxidized wires—missing the best repair time. Delayed part replacement: Wear parts like springs and seals have a clear service life (usually 1-2 years), but users often replace them only when fully damaged, leaving the starter running “faulty” until total failure.

(2) Three Risks of Poor-Quality Starters

To save costs, many choose cheap, unbranded starters, but they increase long-term expenses: Frequent breakdowns (lifespan 1/3 that of quality ones like Cqstart, with 2-3 monthly faults); engine damage (weak gears break easily, with fragments harming cylinders/cranks, costing tens of thousands to repair); high long-term costs (1-year total cost 3x that of quality starters, including replacements and downtime losses).

(3) Solution: Choose Cqstart Quality Starters + Regular Maintenance

Opt for low-maintenance, durable Cqstart starters—made with quality alloy gears, aging-resistant rubber, and tight seals (reducing dust/water entry). Inspect exteriors every 6 months (no frequent disassembly). Check for rust, oil leaks, or loose screws monthly; clean internal dust yearly (per manual, no professional tools). Replace seals and lubricant every 2 years (per manual) to avoid “hidden faults.”

Part 5. Quick Troubleshooting Checklist for Immediate Use

When a diesel engine won’t start, follow this checklist to repair the problems—most issues can be resolved within 10 minutes.

- Pair starter and engine displacement: Record the engine displacement (e.g., “8L”) on its nameplate, then examine the starter model (e.g., Cqstart Series 2 fits 7-10L) to see if they are mismatched.

- Check for water/oil/salt spray damage: Inspect for rust or oil on the starter’s exterior; listen for strange sounds when pressing the start button. Wipe water/oil off with a dry cloth—then try again—disassemble to inspect internal parts if it still fails.

- Check installation: Ensure SAE screws are tightened (using a torque wrench for 25-30N・m if loose) and the starter aligns with the engine’s marks.

- Test startup within 10-30 seconds: Follow the steps (including pre-engagement), do not exceed 30 seconds per try. Wait 3 minutes after a failure before retrying; if it fails twice, check other causes.

Summary

Whether you’re a ship operator, construction equipment manager, or emergency rescue team, if you want to completely solve diesel engine startup problems, feel free to contact Cqstart. Share your engine displacement and usage scenario, and the Cqstart team will recommend a customized spring starter solution—making startup failures a thing of the past.