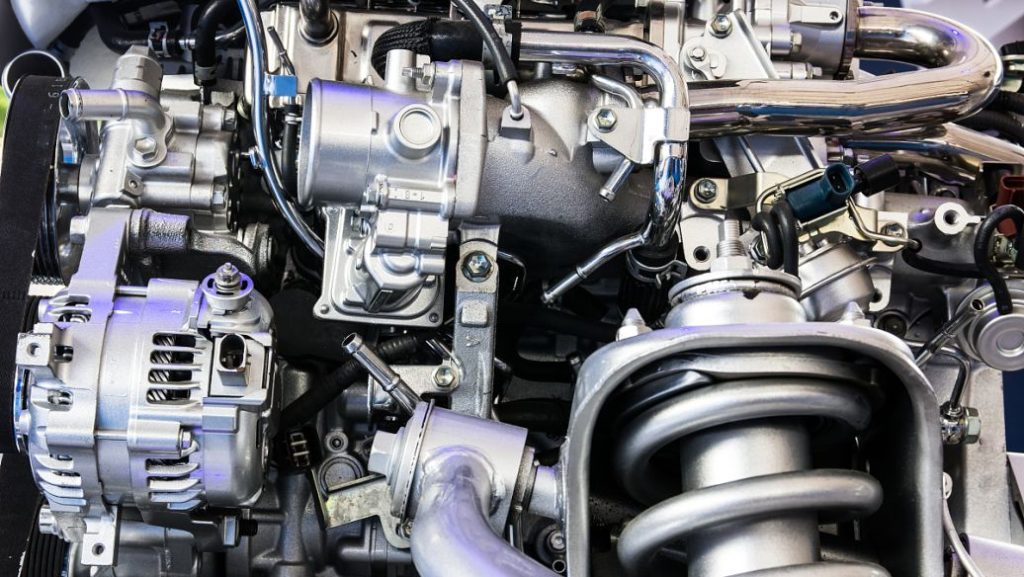

When starting up a diesel engine, often all that can be heard is the starter buzzing and spinning unresponsively; while no engine response occurs. This “spin but not engage” issue can be one of the most frustrating for diesel equipment owners.

Construction machinery, generators, ships or heavy-duty trucks that encounter issues are not only likely to experience delays in work progress; their inactivity also accelerates flywheel ring gear wear through repeated idle spinning, leading to higher maintenance costs. In this article we explore core causes, troubleshooting solutions step-by-step and highlight spring starter-specific issues and fixes so you can quickly identify problems and get them resolved so your equipment runs as intended once more.

Part 1. What “Starter Spins but Does Not Engaging” Mean?

To help you better recognize and address the “starter spins but not engaging” issue, let’s break down its specific performance, common causes in diesel engines, and potential risks:

Intuitive Description of the Fault

At an intuitive level, this fault can be identified when after turning on the start switch you hear high-pitched starter motor buzzing but engine crankshaft doesn’t turn, leading to ignition failure. As opposed to non-responsive starter issues (no current, motor failure) power transmission interruption may be to blame; although starter works normally but its gear fails to engage the flywheel ring gear and block power transfer from happening.

Why It’s More Common on Diesel Engines

The reasons are in three parts. First, diesel engines have relatively higher compression ratios than petrol engines, so when they start, the teeth on the starter gear get re-engaged too often, and they wear out too quickly. Second, diesel engines are usually in rough and dusty outdoor environments, such as construction sites. There is moisture, and cold temperatures that can freeze the starters in a jammed position. Third, faulty maintenance (not enough lubrication, or parts not being replaced in time) increases the chance of an issue becoming a bigger problem.

Potential Hazards

Don’t underestimate its impact: high-speed starter gear friction accelerates flywheel ring gear wear, even causing tooth breakage and costly replacement. In emergencies (emergency power, engineering repairs, ship departure), failed startup leads to delays, economic losses, or safety risks. Thus, timely troubleshooting is critical.

Part 2. Common Reasons Why Diesel Starter Spins but Doesn’t Engage

Users often wonder “what exactly is wrong” when encountering the “spin but not engage” error message. While causes vary depending on which starter type (electric, spring) they use, primary issues often lie within gear engagement mechanisms, power transmission components or installation/maintenance. Here is an analysis of common culprits for most diesel starters:

Faulty Solenoid in Electric Starters

Essential to electric starters, solenoids use battery power to generate magnetic force that pushes drive gear onto flywheel ring gear. However, an improperly functioning solenoid (burned coils, oxidized contacts or broken springs) lacks thrust; motor runs while gear remains stationary – common on older starters or unstable voltage setups.

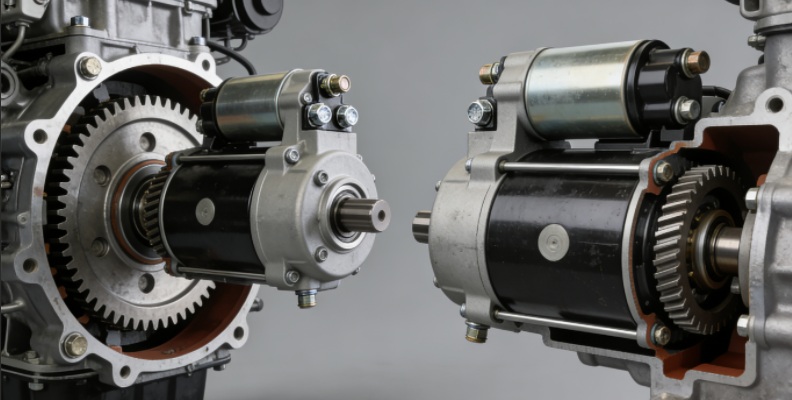

Worn Starter Drive / Bendix Gear

This gear meshes directly with the flywheel ring gear and wears from startup impacts. Worn, deformed, or chipped teeth cause slippage; a failed one-way clutch (ensuring post-startup disengagement) breaks power transmission, leaving the engine unresponsive.

Damaged Flywheel Ring Gear

Attached to the flywheel, its teeth wear, chip, or break over time. Damage causes intermittent or full engagement failure, worsened in cold starts due to higher engine resistance.

Low Battery Voltage (Electric Systems)

Electric starters need adequate voltage. Low voltage reduces solenoid thrust and slows the motor, causing slippage. Common with aging/undercharged batteries or cold-temperature capacity loss (e.g., winter outdoor use).

Misalignment or Loose Bolts

Proper starter positioning is vital. Loose bolts or misalignment misaligns gear and ring gear centers, leading to partial contact, idle spinning, and accelerated wear—from poor installation, vibration, or damaged brackets.

Lubrication Failure: Stuck Pinion Gear

Lack of regular lubrication causes dust, oil buildup, or rust, jamming the gear. A stuck drive gear can’t mesh, resulting in idle spinning—prevalent in outdoor, high-humidity, or dusty environments.

Part 3. Spring Starter-Specific Faults and Solutions

As one of the primary methods for starting diesel engine vehicles, spring starters have long been utilized as one of the primary means of starting these machines in extreme environments (low temperatures, remote areas without power) or high risk settings such as oil fields or mines due to their all-mechanical structure and no circuit dependence. Their “spin but not engage” faults tend to be concentrated more in mechanical components for easier troubleshooting compared with electric starters.

Unique Fault Causes (All-Mechanical Structure)

Power transmission relies on spring energy storage and mechanical engagement for power transfer; so its faults tend to involve springs and pawl mechanisms as the main sources.

- Spring Energy Is insufficient: Manual winding errors such as insufficient turns or fatigue-induced reduced elasticity can rob main springs of their ability to provide adequate driving force for gear meshing, thus decreasing spring energy and thus leading to insufficient driving force for gear meshing.

- Pawl Mechanism Jam: Rust from moisture exposure, dust/debris clogging or lack of lubrication may impede pawl movement and lead to gear extension and engagement being inhibited.

- Failed Return Spring: Aging or broken return springs leave gear extended after use leading to subsequent attempts at re-engagement failure resulting in failed starts of the gear mechanism.

- Spring Deformation/Breakage: Regular usage, high tension or extreme cold-induced brittleness damage the main spring and reduce its storage capacity for energy storage purposes.

Step-by-Step Troubleshooting (Beginner-Friendly)

Resolve faults without professional tools:

- Energy Check: Wind the spring per the manual (80%-100% specified turns). Replace the spring if resistance is weak or uneven.

- Pawl Cleaning: If energy is normal but gear doesn’t extend, partially remove the cover, clean dust/rust, and apply industrial high-temperature grease (-40℃~80℃ compatible).

- Spring Inspection: Replace main/return springs if broken, deformed, or less elastic (use original accessories for matching tension).

- Engagement Test: Manually release the spring to check gear movement. Rotate the flywheel (power off) to test other ring gear positions if spinning persists.

Spring Starter Advantages Comparison

Compared with electric starters, spring starters offer more prominent advantages in addressing the “spin but not engage” fault—this is the core reason they are highly favored by users in extreme environments.

| Comparison Dimension | Electric Starter | Spring Starter |

| Core Fault Points | Solenoid, circuits, battery voltage | Springs, pawl mechanism, lubrication |

| Troubleshooting Difficulty | Moderate (needs circuit/voltage checks) | Simple (visual inspection of mechanical parts) |

| Maintenance Cost | Higher (expensive solenoid/motor parts) | Lower (lubrication and spring replacement only) |

| Failure Rate in Extreme Environments | High (prone to failure in low temperatures/no power) | Low (-40℃~80℃ compatible, no circuit reliance) |

| Emergency Start Feasibility | Low (battery-dependent, no backup) | High (manual operation, no external power needed) |

Part 4. Preventive Measures: Extend Starter Life & Avoid Repeated Idle Spinning

For both electric and spring starters, “spin but not engage” faults are mostly linked to improper maintenance or operation. The following measures can significantly extend starter life and reduce failures:

| Prevention Type | Specific Operations | Frequency | Applicable Starter Types |

| Regular Maintenance | Clean gears and engagement mechanisms; replenish industrial-grade grease | Every 3-6 months | All types |

| Standardized Operation | Electric starters: Single start ≤5 seconds, interval ≥30 seconds; Spring starters: Wind to store energy per standards | Each use | Corresponding types |

| Environment Adaptation | Low temperatures: Use cold-resistant springs/batteries; High humidity/dust: Check sealing and clean debris | Before extreme conditions | All types |

| Parts Replacement | Replace gears/ring gears with >1/3 wear, fatigued springs, or oxidized solenoid contacts promptly | After detecting issues | All types |

Supplementary Notes

- For regular maintenance: Focus on lubricating pawls and spring connections for spring starters; prioritize drive gears for electric starters.

- Standardized operation prevents human-induced damage (e.g., over-winding distorts spring starters; prolonged use burns electric starter solenoids).

- Environment-adapted parts improve durability and decrease failure risks in extreme conditions.

- Timely replacement of aged parts prevents minor faults from worsening, thus cutting maintenance costs.

Summary

Although “spin but no engage” faults are a frequent occurrence among diesel starters, identifying its root cause can make diagnosis and repair much simpler. Issues often pertain to gear engagement mechanisms, power transmission components (such as springs or solenoids) or installation/maintenance issues.