Diesel generators are engineered to be reliable, yet a lot of power outages do not occur during operation, but instead at the time of startup. If a generator is unable to start, the downtime will increase and maintenance costs increase and crucial systems could be shut down. Most of the time the cause lies in a non-reliable starter device. Selecting the best starter option is among the most effective methods to decrease downtime and increase the reliability of your generator.

This is where the Spring Starter changes the game.

Common Causes of Diesel Generator Downtime

Before you can determine the best solution, it’s essential to know why diesel generators do not begin at all.

Battery-Related Failures

The most common cause of battery failure is reason for generators to stop working. Batteries degrade naturally over time, they lose their charge during prolonged standby times, and fail in cold temperatures. In the event of an emergency an unbalanced or damaged battery could completely stop the engine from starting even when it’s in good shape.

Electrical Starter Motor Issues

The traditional electric starter motors depend on a variety of electrical components, comprising relays, wiring, along with control circuits. Exposed to vibration, moisture dust or corrosion can lead to failure. If electrical problems occur Troubleshooting and repair could significantly prolong downtime.

Infrequent Use and Emergency Conditions

Standby generators may remain idle for months before being required to start immediately The equipment experiences battery drain and power system deterioration because it remains unused for extended periods. The most critical times for generator operation occur during blackouts and extreme weather conditions and natural disasters because electrical systems experience their highest failure rates.

Why the Starter Device Plays a Critical Role?

The starter device will determine whether an engine can switch from standby to operational quickly and effectively.

Startup Reliability Equals Uptime

Generators that aren’t able to begin immediately is not worth the cost. A reliable startup is directly related to more uptime, especially when it comes to backup power solutions that support hospitals as well as industrial facilities, data centers remote operations, and hospitals.

Reducing Failure Points

Every electrical component has an opportunity for failure. Starters that rely heavily on batteries or electronics add the complexity of the system. However, simple starting mechanisms decrease the possibility of unexpected interruptions.

Faster Response in Critical Situations

If power goes out the time of day is crucial. A reliable starter device reduces the time it takes to restart, minimizes operator involvement and helps ensure generators are up and running as fast as they can.

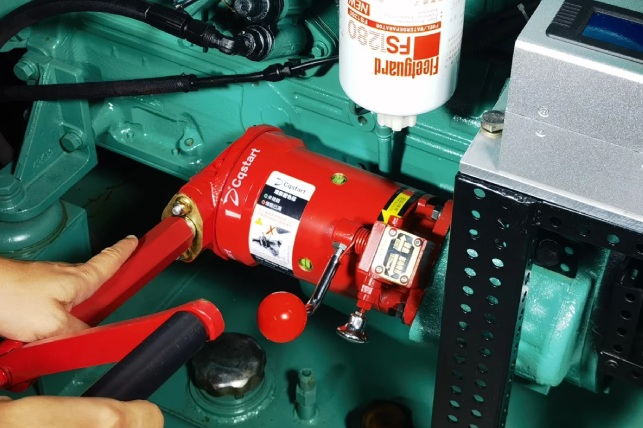

Why Spring Starters Are a Proven Solution?

The diesel generator applications for which spring starters provide a practical solution because they solve common startup problems.

Always Ready to Start

Spring starters maintain their functionality because they operate without requiring battery power or external electrical systems. This makes them especially suitable for emergency backup generators.

Reduced Electrical Complexity

The electrical components in spring starters have been minimized to the point that their system operates without needing wiring or relays or control systems. The system experiences fewer chances of malfunction because it contains fewer components.

Strong Performance in Extreme Conditions

Spring starters function effectively in cold environments and offshore sites and remote industrial areas because these systems do not need electrical power to operate. Their mechanical design provides reliable operation during tough working environments.

Long-Term Reliability

The installation and regular inspection process enables spring starters to deliver extended service life together with consistent operational performance. The system provides dependable performance which decreases generator downtime while enhancing operational reliability for users.

Key Benefits of Using Spring Starters on Diesel Generators

Increased Generator Availability

Generators equipped with spring starters are ready to start at any time, regardless of battery status or power availability. The system maintains constant readiness which decreases all possibilities of equipment downtime.

Lower Total Cost of Ownership

Although initial investment costs need to be considered, the actual expenses throughout the entire operational period become the most essential factor. The total operating expenses decrease because there are less startup failures and the system requires less maintenance and equipment needs to be replaced less often.

Improved Safety and Simplicity

Emergency situations become safer because operators face reduced dangers through simplified startup procedures. The removal of high-current electrical components provides better safety protection for operational activities and maintenance work.

How to Choose the Right Starter Device for Your Generator?

The selection process for suitable starter equipment requires thorough examination of multiple assessment elements.

Match the Starter to Engine Requirements

The starter system needs to match the specific requirements established by the engine.

Starter devices require enough torque capacity to start engines which face their maximum compression state. The proper size of equipment components permits engine operation without excessive mechanical stress which maintains successful start sequences.

Evaluate the Operating Environment

Starter devices need to maintain functionality when they encounter outdoor conditions and marine environments and industrial sites which expose them to moisture and corrosion and extreme temperature changes. The system needs environmental compatibility to achieve extended operational reliability.

Consider Ease of Installation and Operation

The starter device needs to function as a generator system component which operators should find easy to handle. The system allows operators to complete their tasks through both quick setup and simple operation which decreases operational delays that result from setup mistakes or improper usage.

Choose Proven Quality and Support

Dependable performance results from using high-quality materials and accurate engineering designs which receive continuous backing from manufacturers. The selection of a reliable starter solution will protect system availability throughout its operational lifespan.

Reduced downtime of diesel generators starts by addressing the most frequent problem: the start-up. Starters that depend on batteries often fail in extreme conditions, emergency situations or prolonged standby times. When choosing an effective starter device, a spring starter in particular, can dramatically increase reliability during startup, decrease downtime, and make sure the power source is always available whenever it is required. A good starter can transform an generator that was originally to a backup solution into a reliable power source.