Are you stuck with the Perkins diesel engine, which can’t start at remote work sites cold temperatures, freezing temperatures, or power failures? Batteries that are dead, defective electric starters, or cold-weather challenges can grind the work process to stop, costing time and money as well as frustration. In these crucial moments electric power isn’t something you have. The positive side? Spring starters are a simple, reliable solution that’s mechanical power can transform a dead battery crisis into a straightforward, easy turning of a handle.

Why Traditional Starters Fail for Perkins Diesel Engines?

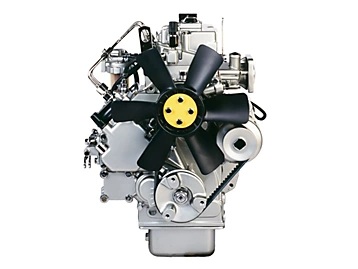

Perkins diesel engines power critical equipment ranging from construction machinery and farm generators to vessels for marine use and emergency backup systems. However, their most popular starters are often not adequate under real-world conditions. Electric starters rely on batteries that are prone to draining in cold temperatures (temperatures below -10℃ could reduce the battery’s capacity by 50% or more) and can leave people stranded on off-grid areas. They also require frequent maintenance. Battery replacements, motor repairs and wiring inspections add up over time. For Perkins users working in areas that have a loss of revenue due to downtime, such as mining or healthcare, problems aren’t just annoying; they’re also costly. Spring starters reduce these risks by using an easy, mechanical design that can be used even when electric starters don’t.

Why Choose a Spring Starter?

Spring starters are now an essential part of the toolkit for a lot of Perkins diesel engines. Here’s why:

- Effectiveness: Spring starters give an energy boost for the engine at startup especially when batteries are weak or the temperatures are cold. This could significantly increase the probability of an efficient start.

- Reliability and Durability built to last. spring starters need minimal maintenance and are very durable, which makes them an affordable option in the long run.

- It can be used in extreme conditions: Whether it’s extreme temperature or high elevations the spring starter has been specifically designed to work in difficult conditions where other methods of starting might fail.

How to Start a Perkins Diesel Engine with a Spring Starter

Step 1: Check the Engine and Starter

The complete system of your Perkins diesel engine needs to be tested for starting. Check the fuel level, oil level, and coolant. The spring starter needs to be examined for any visible damage which includes cracks and loose components.

Step 2: Ensure the Spring is Tensioned Properly

The spring starter requires proper spring tension as its main operational component. The spring needs to be wound and tensioned correctly because it needs sufficient mechanical force to operate the startup process. The manufacturer provides guidelines which you must follow to accomplish safe and secure spring winding.

Step 3: Start the Engine

The engine can now be started because the spring has achieved its correct tensioning. The engine starting process requires you to activate the spring starter system which you do by pulling a lever or rotating a handle. This action should help the engine turn over more quickly, assisting with ignition.

Step 4: Post-Start Checks

The Perkins engine needs a brief inspection after it starts running. The technician needs to check three components which include oil pressure and coolant levels and any noises that fall outside the expected range. The process verifies that all system components function according to their intended design.

Spring Starters Solving Perkins Startup Problems

Don’t believe us? Here’s what spring starters can do to revolutionized Perkins Engine reliability and performance for actual customers:

Mining Site Success

A coal mine located in Australia was powered by an Perkins 1106 engine for powering the crusher. Its remote location meant that it was not connected to power grids and battery-powered starters would fail each week. When switching over to spring-powered starters the engine was able to start consistently 8 times per day and reduced time to failure by a quarter and reducing $15,000 monthly expenses.

Cold Climate Win

A farm in northern Canada used a Perkins 403 backup generator for greenhouse heating. The electric starter became nonfunctional when winter temperatures reached their lowest point at -35℃. The generator started through a spring starter which operated for 30 seconds to maintain crop growth and prevent $20,000 in potential damage.

Emergency Lifesaver

An institution in UK was dependent on the Perkins 1200 Series generator to provide emergency power. After a sudden blackout the electric starter went out of commission. The spring starter was activated immediately, providing the power supply to the intensive care units while helping save the lives of patients in critical situations.

Invest in a Spring Starter for Hassle-Free Perkins Startup

If you’re fed up of failing electric starters as well as battery-related headaches or even the dreaded cold-weather startup problems with the Perkins diesel engine spring starter is the solution that will change your life. It’s reliable, low-maintenance and is designed to work when traditional starters fail, be it in remote mining area, a the freezing temperatures of a farm, or a an emergency settings. Easy installation, simple operation, and tested real-world outcomes spring starters will take all the hassle from the process of starting an Perkins engine. Get one now and enjoy smooth, reliable start-ups for the years to come.

FAQs: Spring Starters for Perkins Diesel Engines

Q1: Do I have to alter the engine of my Perkins engine to include spring starters?

No--spring starter is made to be able to mount Perkins original mounting points. They are supplied with all the necessary equipment, and installation can take about 1-2 hours using the most basic tools.

Q2 What is the maximum number of times I keep energy stored in the spring starter?

It’s no limit. may recharge the battery as often as you need to without causing damage to the device. One charge can support 2 restarts.

Q3 What about spring starters? Will they fit on my existing Perkins engine?

Yes, spring starters work with the new and older Perkins models, which include the 300 series as well as the older engines of the 4000 series. For unique or customized models manufacturers can provide customized solutions.

Q4: What’s your life expectancy of the spring starter?

If properly cared for spring starters can last for more than 10 years. They’re constructed using high-strength stainless steel springs and materials that resist corrosion to withstand the harsh conditions of industrial use.