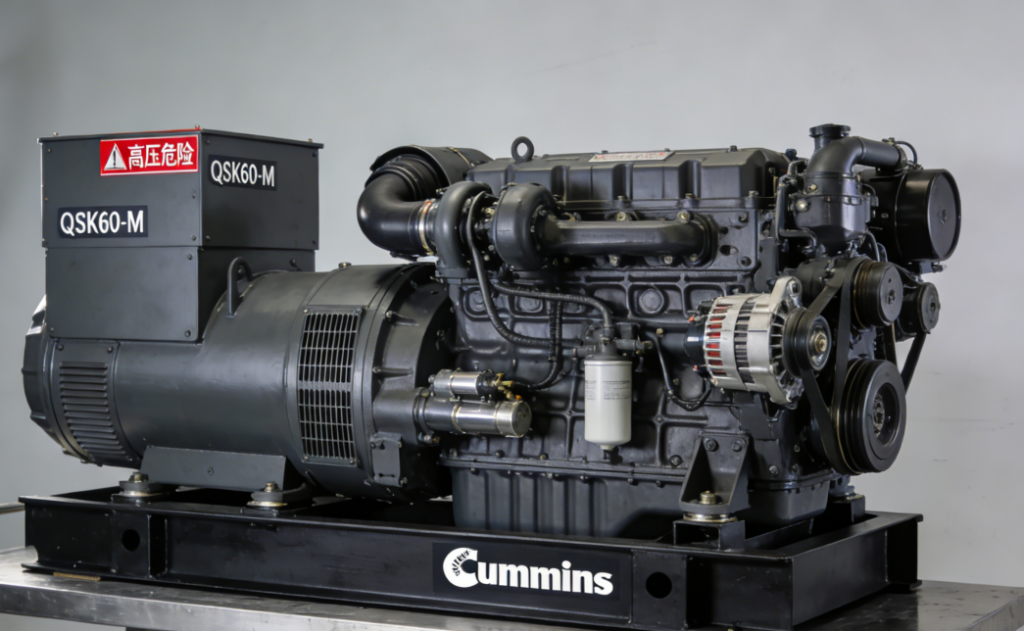

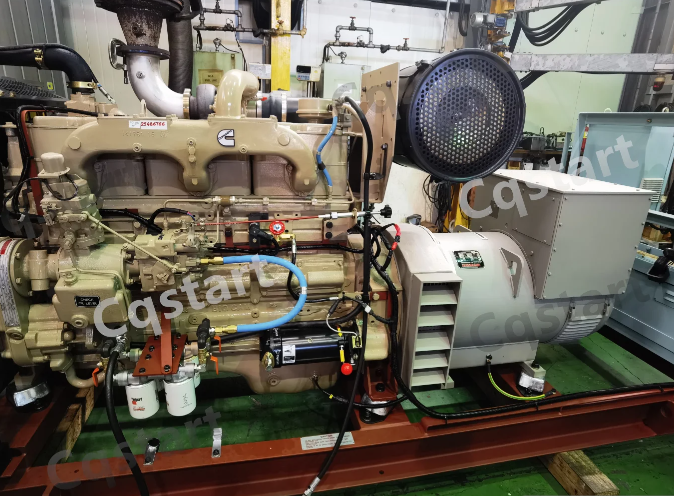

Starting a Cummins marine engine while dry-docked is a specialized procedure distinct from in-water operation, requiring strict adherence to technical protocols to avoid costly damage.

Today, we will talk about how to start a Cummins marine engine dry–docked, as well as the important preparations , precautions, solutions to common problems, and how to select the right spring starter. Mastering these specifications will ensure the protection of your Cummins engine during dry-docked operations and reduce the risk of component failure.

The Key Differences Between Dry Start-up and Water Start-up

During water start-up, seawater is pumped through the engine’s cooling system to manage the temperature, thus protecting the impeller, as well as the cylinder head. During a dry start, there is no natural coolant, and thus, the engine’s natural cooling system may cause the engine to overheat within seconds. It is in this respect that Cummins’ marine diesel engines are equipped with additional cooling systems during dry dock tests.

Secondly, water start-up is for navigation, while the dry start-up is for testing, maintenance, as well as repair of the engine, with the process taking no more than 10-15 seconds during each attempt.

Preparations Before Starting the Cummins Marine Engines Dry-Docked

Proper preparation is 90% of the job. In order to prepare the Cummins marine engine for starting carefully, regard the following instructions as a supplemental to Cummins start-up inspection list:

Auxiliary Cooling Setup

Install a freshwater flushing system or connect a portable cooling unit to the engine’s cooling inlet. Ensure the loop is sealed and filled—this mimics seawater cooling and protects the impeller.

Fluids Check

The crankcase oil level should be within the L and the H range of the dipstick. Fill in the coolant expansion tank to 75% and inspect hoses and gaskets for any possible leakage. The fuel system should be purged of air, in this case, open the fuel filter drain valve until clean fuel discharges, then retighten.

Electrical System Inspection

The battery must be verified (it should be 24-28V on most units) and the terminals must be free of corrosion and tighten if they are loose—failure of a Cummins marine engine occurs as blasted sulfate over the terminals. The wires should be free from tears especially those going to the starter engine and the control panel.

Mechanical Checks

Turn the engine over a full revolution using the turning gear to ensure that there has been no internal seizure. Remove any tools, rags, etc., that may be in the engine bay, as these can cause damage. Exhaust hoses must be checked for cracking and the exhaust system must be correctly vented to avoid backpressure.

Control Panel Prep

Change the engine to manual mode. Check that all warning lights and gauges are functioning correctly. Set throttle to idle position (750 rpm for most Cummins engines).

How to Start a Cummins Marine Engine Dry-Docked

With prep complete, follow these step-by-step instructions for a safe dry start. This process works for most Cummins marine diesel engines:

Step 1: Activate Preheating

When the outside temperature is cold (below 50°F/10°C), make sure that the engine pre-heater is turned on and left on for 2 to 3 minutes. This step helps much with combustion and reduces strain on the marine engine starter. Most of including Cummins marine engine come with a built-in preheat indicator light. If temperature is above 50°F/10°C, you can skip this step.

Step 2: Engage the Starter

This is achieved by the start button or ignition key being turned. Do not crank for more than 10 seconds; as this will cause damage to starter motors, fuel systems and even other parts of Cummins engines. If the engine can not start in 10 seconds, desist from holding the start button for any longer and wait for a minute to allow the starter motor to cool. This prevents starter overheating and enhances its durability.

Step 3: Monitor Initial Operation Closely

Once the engine starts, one has to make sure that oil pressure builds in the first 10sec after the engine starts that is, check the oil pressure gauge (refer to the specific Cummins marine engine manual for the mentioned oil pressure values). In addition, observe the temperature of the cooling agent to confirm the operation of the supplemental cooling system. The engine speed should be kept at idling speed (750rpm for most Cummins models). Pay attention to detect any strange noises such as knocks, squeals or grinds, and check if there are any fuel, oil or coolant leaks.

Step 4: Adhere to Strict Run Time Limits

The dry run time should not exceed 2 to 3 minutes of the run total for the Cummins marine engine. This extreme brevity lets you measure the critical systems (pression, cooling, absence of leaks) without overtaxing components. If longer engine testing is required for repair or maintenance of the dry-docked engines, install an extended auxiliary unit and provide periodical coolant temperature measurements every 30 seconds to prevent overheating.

Step 5: Shut Down the Engine Properly

Testing is completed, turn off the power of the engine either through panel control or choose using the switch. Do not close the cooling system immediately after stopping the engine without letting it work for another 60 seconds allowing the engine to cool down slowly. It prevents thermal stresses which may cause damage to gaskets and cylinder heads. After 1 minute, unmount the auxiliary cooling equipment and drain all the water remaining inside the cooler circuit to avoid corrosion during dry docking of the engines.

Precautions for Starting Cummins Marine Engines Dry-Docked

Dry starts carry inherent risks—these precautions will protect your engine and ensure compliance with safety standards:

- The engine must not be cranked when the auxiliary cooling system is not in operation. Because the impeller may get damaged beyond repair.

- Repetitive start of the engine must be avoided. The starter will be weakened if more than three crank starts are made within 5 minutes.

- Ensure no personnel are near moving parts (belts, pulleys) during start-up. Secure loose hoses and wires to prevent entanglement—dry docks are cluttered, so extra vigilance is key.

- Do not allow anyone near the moving parts during the process of start-up. In order to avoid possible entanglement of loose hoses or wires, it is necessary to secure them properly.

- If you need to replace components before starting, use Cummins marine engine parts only. Aftermarket parts (especially gaskets and filters) may not seal properly, leading to leaks or system failure during testing.

- Always verify water flow from the exhaust first. If no water flows out, the operation should be stopped immediately.

- Be wary of the chaotic nature of carbon monoxide. Even though we are within a dry dock, there might be excessive exhaust build-up. Ensure there is enough room for some fresh air.

Common Issues and Troubleshooting of Cummins Marine Engine

Low charge is the most common reason for this problem. Examine the terminals in case they need to be unhooked and cleaned, or jumped charged the battery. If the starter just clicks when trying to start, check the belt of the starter motor (should flex 25-30 mm by hand) and adjust the tension or change it if required.

Engine Starts but Dies Immediately

Most of the time this means that there is some air in the fuel line. Once again carry out bleeding of the fuel system lines (refer to Cummins’ preferred access points for bleeding) and see whether the fuel lines are secure. However, if this persists, the filter has to be checked as clogged filters will lead to engine underfueling.

Overheating Warning

Shut down the engine. Verify the auxiliary cooling system—conform as to whether it is well attached and functional carrying water. Measure the level of the coolant and look for any drippings. There is always the possibility of a false positive alarm due to a damaged sensor, so a multimeter can be used to check it.

Unusual Noises

A belt riding on a pulley or a loose pulley or a bad bearing gives a squealing noise – stop and check the belts and the pulleys respectively. Internal problems are indicated by a knocking or grinding noise. Stop operation immediately and schedule a marine Cummins engine repair.

Oil or Fuel Leaks

Turn down the engine and look for the source of the leak. Loose fittings should be tightened and damaged gaskets replaced using Cummins marine engine parts. If the leak still persists, the engine should not be operated because of the fuel leakage which presents a fire risk and a leak of oil which causes insufficient lubrication.

How to Select the Right Spring Starter for a Cummins Marine Engine Dry-Docked

A reliable spring starter is critical for dry-starting Cummins marine engines. The first step requires you to select a starter which provides appropriate torque for your Cummins model based engine displacement requirements because insufficient torque prevents engine starting while excessive torque results in gear damage. The housing material needs stainless steel or coated aluminum which resists corrosion while the IP-rated seals must protect against dusty and damp conditions present in dry dock environments.

Besides, manual starters work best for small engines while larger Cummins units should use semi-automatic starters because they require less physical effort. You must confirm mounting compatibility between your Cummins model and its parts catalog which includes authorized dealers to prevent misalignment issues and equipment damage. Always choose a trusted marine brand like the Cqstart Spring Starter; generic starters have short lifespans and may void your Cummins engine’s warranty.

Conclusion

Starting a Cummins marine engine dry-docked requires careful preparation, strict adherence to step-by-step procedures, and constant attention to safety precautions. To boost reliability, choosing a renowned brand like the Cqstart Spring Starter is a wise decision.