Hard starting is usually the bane of diesel equipment owners. Diesel engines operate using compression, which often results in cranking, fuel system, and pre warm-up issues—key factors behind what is the cause of hard starting in diesel engine.

This article outlines six possible causes of this problem, viz., weak battery, glow plugs failure, low compression, fuel system failures, clogged fuel filters. The article further provides symptoms and solutions of these causes. It also contains tips for maintenance and troubleshooting of the diesel engines that will help prevent dispel problems and deal with them more effectively, without resorting to frequent expensive repair services and keep equipment running smoothly.

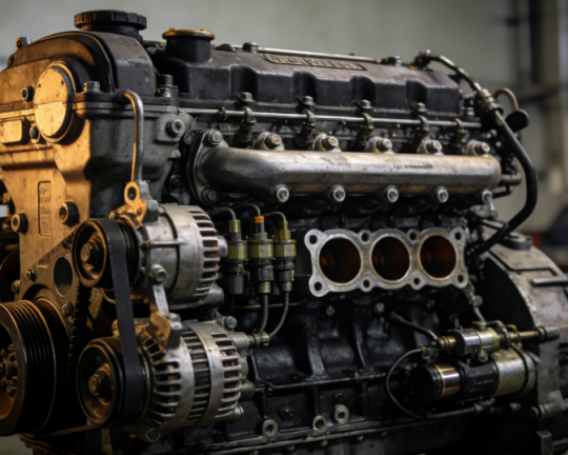

How Does a Diesel Engine Work?

Diesel engines, operating on the principles of compression and combustion, unlike gasoline engines which are based on the use of the spark plug, have high compression ratios of approximately 16:1 to 22:1 to initiate the combustion of the fuel. The process can be divided into four stages as follows:

- Intake Stroke: Air is drawn into the cylinder.

- Compression Stroke: During the compression stroke, the piston pushes the air to a small area and the temperatures rise to over 400 and 752 degrees Fahrenheit respectively.

- Power Stroke: On reaching the optimum pressure the working gas received the fuel directly, supporting its self-ignition and propulsion of the piston to move downwards.

- Exhaust Stroke: Combustion products are released.

This requires: enough energy for cranking of the engine especially at the beginning, fuel delivery system and preheat in winter seasons. It is for this reason that understanding how does a diesel engines work can better address the problems of diesel engines especially when it comes to hard starting; every aspect from compression, to fuel, to heat—the crucial elements of starting the engine may be compromised.

What Is the Cause of Hard Starting in Diesel Engine?

A diesel engine requires three key elements to start: high compression heat, precisely timed fuel injection, and adequate cranking speed. When any of these elements is compromised, hard starting occurs. The following sections break down the most common failures, their symptoms, and solutions to guide your troubleshooting.

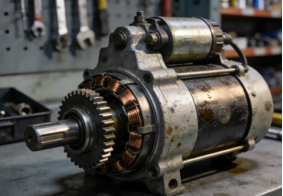

1. Weak or Failing Batteries and Starter Motor

Cause: One of the most important characteristics of a diesel engine is its high compression, far greater than that of a gasoline engine, and this means the cranking power needs to be far greater. The power required for the engine to crank may be insufficient due to weak or failing batteries, corroded or loose terminals, a faulty starter motor or even a problem with the charging system hence resulting in hard starting.

Symptoms: Hesitant engine start as in the engine turns over less vigorously than normal or only clicks from the starter solenoid but not work as intended are typical symptoms. In low temperatures, of course, this problem is even worse as the battery loses one percent of capacity per each degree below 32 degrees Fahrenheit, and so weak batteries even slightly are unable to cope with cranking. In certain situations, when the key is turned on, dash lights dim, demonstrating that there’s not enough power flow.

Solution: Check the battery charge and do a battery inspection to test its performance. All battery connections including ground should be cleaned and properly re-connected. Have a diesel engine repair service test the starter motor and charging system to identify any further issues, helping in fixing diesel engine starting problems effectively.

2. Glow Plug or Intake Heater System Failure

Cause: Glow plugs and intake heaters are critical for cold start diesel engine performance, as they warm the combustion chamber to ensure fuel ignites properly. Over time, glow plugs often burn out, carbonize or short circuit. Faulty relays, control modules, or damaged wiring can also prevent the system from heating correctly, especially in low‑temperature conditions.

Symptoms: In cold weather (below 5°C), the engine cranks many a time but does not start or starts harshly and throws out white smoke (unburnt fuel) from the exhaust pipe. The indicator light for glow plugs on the dashboard may similarly be faulty— remaining out turned on for longer than necessary, blinking or not turning on at all.

Solution: The best thing to do is to take a multimeter and check the individual resistance of each of the diesel engine glow plugs available. If the reading is infinite then it means that the plug is burnt out and a replacement is needed. Carry out a physical inspection of the wiring and plugs, checking for any damage. Ensure that the relay or regulator has a working voltage. Do not handle issues of the intake heater, instead, go to a diesel engine repair service who will test and replace faulty parts in the system.

3. Air in the Fuel System

Cause: It is not rare to observe air being introduced in the diesel fuel system due to the existence of fuel pipes/fuels which can be worn out, disused or fuel filter replacing. At a tame state of the engine, diesel must be injected continuously without air that can separate and cause no fuel to each cylinder. This problem is mainly for the older engines and systems where the components of the fuel system are worn out.

Symptoms: The engine is rough and erratic when starting or and within seconds stops running or refuses to start completely. There is an apparent loss of power or the engine runs erratically as if it is being suffocated. Air bubbles are visible in transparent fuel pipes leaving the fuel pump (Their presence will signal the existence of fuel starvation). There will also be a spray-like noise or dropping power if the air is sucked in and out of the system as the car moves.

Solution: Purge the fuel system according to the procedure set by the manufacturer- find the bleeding screw (normally on the fuel filter or on the injection pump) and loosen it, crank the engine until fuel without air bubbles comes out. When you see clean fuel, re-tighten the bleed screw, then restart the engine. Check the fuel pipe connections, the O-rings and the seals for any possible leaks and replace if damaged any. In fuel filters replacement, the new filters should be first filled with diesel to prevent air entry into the system.

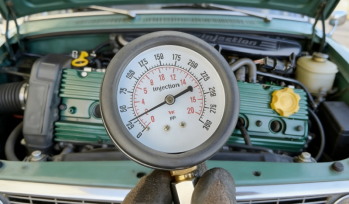

4. Low Compression in Engine Cylinders

Cause: A diesel compression engine depends on compression ratios of 16:1 to 22:1 to ignite fuel, so any loss of pressure disrupts ignition. Most common include worn out ring pistons (excessive mileage or use of bad oil), impaired valves or valve seats (air leaking during compression), blown gaskets (air leaking between the engine cylinders) or warped cylinder heads (due to over heating). This is even common in engines that have clocked 200,000 miles and above or have previously over heated.

Symptoms: Engine cranks normally but doesn’t start or it starts but idles and it’s shaking too much. Hard starting is often accompanied with weak power output, high fuel consumption or blue or white smoke from the exhaust (which is a sign of oil or coolant leaks). In some cases, the engine may start when cold but stall as it warms up, as metal expansion worsens compression leaks.

Solution:The best solution is usually to book a compression test with a reliable diesel engine repair service. They will measure cylinder pressures and identify any leaks. Repairs depend on the cause: worn piston rings require an engine overhaul, damaged valves need replacement and resurfacing, and a blown head gasket can often be fixed with a proper cylinder head inspection. The repair is so serious and it takes time and effort, so early detection through regular checks is important to reduce costs.

5. Fuel System Failures

Cause: Fuel system failures include problems with injectors, fuel pumps, or fuel quality. Clogged injectors won’t work properly, the pump too weak will not be able to create pressure. Bad fuel (water, dust, sediment, etc) causes parts wear and affects the flow of fuel, and the engine becomes difficult to start.

Symptoms: Clogged injectors cause black smoke, rough idling, and extended cranking before starting. Leaking injectors may lead to a strong diesel scent, loss of mileage, or hard starting due to low fuel pressure. When the fuel delivery system component wears out, the engine will experience the hard start condition especially hot starting and it will cut off on load. When the fuel pressure regulator has malfunctioned, the engine may begin but then cut off abruptly due to irregular changes in the pressure.

Solution: At least one high quality fuel system cleaner can be added into the tank about every 3 to 5 thousand miles in order to treat any blockages or deposits. Have a diesel engine repair service test fuel pressure to diagnose pump or regulator issues. If the components are faulty, they will need to be repaired or replaced. In addition, always use fresh and high-quality diesel. And if the engine is likely to remain inactive for thirty days or longer, then fuel stabilizer additives should be added.

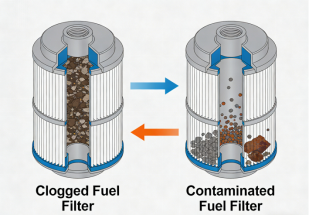

6. Clogged or Contaminated Fuel Filters

Cause: Fuel filters can trap dirt, sediment, and water, thus keeping the fuel system free from contamination. But over time, these filters may become clogged due to impurities. Dirty fuel or long replacement intervals further aggravate clogging of the filter to such an extent that fuel inflow to the engine is reduced. Ignoring diesel engine maintenance will accelerate this problem.

Symptoms: You may find a gradual power fade and engine hesitancy when the engine is under load, and there will be difficulties in starting. This condition will gradually worsen, eventually leading to the complete inability of the engine to ignite due to the blockage of the fuel filter. At the same time, the engine may also stall at idle or during acceleration.

Solution: To prevent fuel-related problems in your diesel engine, you should follow a proactive maintenance routine, including replacing fuel filters at the intervals specified in the maintenance schedule or more frequently under harsh operating conditions. Regularly drain the accumulated water in the separator through the drainage valve on the filter housing, and use high-quality fuel to reduce the risk of pollution.

Daily Prevention & Quick Troubleshooting Tips

Daily Prevention

Routine diesel engine maintenance is the best way to prevent hard starting.

- Charge the batteries and clean all the terminals before winter .

- Change fuel and air filters on schedule.

- Check the condition of the diesel engine glow plug monthly.

- Use high-quality fuel and keep the tank above a quarter full.

- In cold weather, purchase a battery warmer to give a good crank to your cold start diesel engine when needed.

- Long-term storage requires periodic engine starts to preserve mechanical performance.

Quick Troubleshooting Tips

- Check battery voltage and terminals;

- Check the glow plug indicator;

- Confirm that there is adequate fuel in the tank and that the fuel filter is clean;

- Remove any air in the fuel lines;

- Use fuel injector cleaner.

- If these steps fail, ask a diesel engine repair service for help.

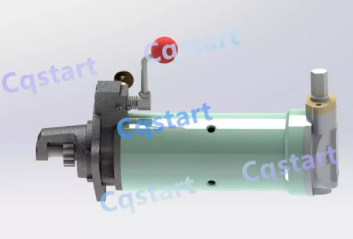

Cqstart Spring Starter: Emergency Solution for Diesel Engine Hard Starting

Even with proper maintenance, some unexpected situations(like a dead battery in remote locations) can leave you stranded. The Cqstart Spring Starter is a reliable emergency backup for fixing diesel engine starting issues when electric start fails. The spring starter is a modern power device that eliminates battery and external power since it uses mechanical energy storage to cause the crankshaft to rotate.

Ideal for field operations, construction sites, or generators, it supports cold start diesel engine needs and works with most diesel models. Its installation is simple and preserve the original electric start system for daily use. For situations where a diesel engine needs to be started quickly, Cqstart provides peace of mind without waiting for diesel engine repair service.

Conclusion

Hard starting in diesel engines typically results from failures in the electrical, fuel, or compression systems. Regular diesel engine maintenance, such as checking batteries and replacing filters is key to prevent the problem.

For emergencies like remote dead batteries, Cqstart Spring Starter is a reliable battery-free backup. It guarantees the ability to start a diesel engine when all else fails, offering ultimate peace of mind and operational security for any diesel-powered asset.