Engines that have been unused for extended periods differ significantly from those that are started regularly. Fuel may degrade, deposits can accumulate in the fuel lines, oil viscosity may change, carbon buildup may increase, and the battery may even be discharged. Ignoring these issues can lead to difficulties in starting the engine or even cause damage. Today, we will provide a detailed guide on how to start a diesel engine that has been sitting, along with maintenance and preventive recommendations.

Step 1: Inspect the Engine and Fuel System

Before attempting to start a diesel engine, it is essential to perform a thorough inspection of the engine and fuel system, especially if it has been sitting idle for a long period.

Check Engine Oil and Coolant: After long-term storage, engine oil may degrade or become contaminated, and coolant may evaporate or get polluted. Check the levels and condition of both oil and coolant. If the oil appears dark or viscous, replace it with fresh oil and top up to the proper level. Inspect the coolant for impurities or signs of corrosion, and replace it if necessary.

Check Fuel Condition: Diesel fuel can oxidize or absorb moisture. This can cause a cloudy or dirty appearance or an unusual odor. Before start-up, inspect the fuel condition. If the fuel is bad, replace it with fresh diesel fuel. This can prevent problems with the diesel startup injection system.

Inspect Fuel Lines: Confirm that fuel lines are not cracked, leaking, or corroded. Fuel lines with blockages will prevent the engine from starting upwards because fuel is essential for starting an engine.

Fuel Filter: If the fuel filter is old and has not been replaced in quite some time, it could be clogged and hence interrupt fuel flow. Change it with a new one before proceeding.

Using good quality diesel and fuel additives or stabilizers may increase the useful life of the fuels and decrease the possibility of starting problems after long-term storage.

Step 2: Check the Battery and Electrical System

The battery is a critical component for starting a diesel engine, especially after extended periods of inactivity, as it can discharge or lose capacity.

Check Battery Voltage: Use a multimeter or voltmeter to measure the battery voltage and ensure it is within the normal range (typically 12V or 24V, depending on the system). Low voltage may prevent the starter motor from operating correctly.

Inspect Cables and Terminals: Ensure battery terminals are tight and free from corrosion or oxidation. Loose or corroded connections can reduce current flow, affecting startup efficiency.

Charge or Replace the Battery: If the battery is low, fully charge it with a battery charger. If it is old or damaged, replace it to avoid startup failure.

Assisted Starting Devices: For industrial diesel engines or heavy-duty engines, the use of spring starters or other assisted starting devices can provide the necessary starting power to the engines, enabling it to start smoothly.

Battery performance tends to decrease more significantly when it is cold. It should, therefore, be well charged to ensure smooth starting every time.

Step 3: Fuel Bleeding and Filling

After a diesel engine has been sitting idle for an extended period, air can accumulate in the fuel lines, causing restricted fuel flow and making starting difficult. Proper fuel bleeding and filling are essential to ensure smooth engine startup.

Bleeding the Fuel System:

A manual pump or electric pump can be used to slowly pump the air out of the fuel line. The fuel can be carefully observed until it starts to come out steadily and there are no signs of air bubbles in the fuel.

For those engines with a fuel return, the manufacturer’s recommendations should be followed to purge air from those return lines as well to ensure the fuel system is properly pressurized.

Filling the Fuel System:

After cleaning the fuel system of any air, fresh diesel fuel should be added to the fuel pump and injectors.

Verify that the fuel pump is working well, supplying fuel consistently to the injectors, so that there is fuel for ignition by the engine.

Tips:

- Proper fuel bleeding prevents engine idling issues, black smoke, or difficulty starting.

- Even if the battery and starter motor are in good condition, residual air in the fuel system can prevent the engine from starting smoothly or cause unstable operation.

- Always operate safely and avoid fuel leaks near hot components to prevent fire hazards or equipment damage.

Step 4: Properly Starting the Engine

After completing the inspections and fuel bleeding, starting a diesel engine requires careful operation to protect engine components and ensure a smooth start:

Low-Speed Start:

Use a low-speed start mode and avoid high-speed cranking for a long time. Excessive stress on the starter motor, flywheel teeth, and crankshaft can cause damage to these parts if the engine has been standing still for a while and the lubrication inside the engine has not been evenly distributed.

Intermittent Starting Attempts:

If the engine is difficult to start, use intermittent cranking. Crank for a few seconds, then wait 10–20 seconds before trying again. This prevents the starter motor from overheating, the battery from over-discharging, and ensures stable fuel system pressure, improving the likelihood of a successful start.

Cold Weather Preheating:

However, when the temperatures are too low, the diesel may gel, and the fuel may not atomize well. This may affect combustion. Using glow plugs for pre-heating ensures that the engine is heated well before the fuel atomizes completely. Pre-heating depends on the temperature and type of engine. This process commonly requires between 10 to 60 seconds of pre-heating. During this process, gentle pressing of the accelerator ensures rotation of the engine using low speed.

Using Assisted Starting Devices:

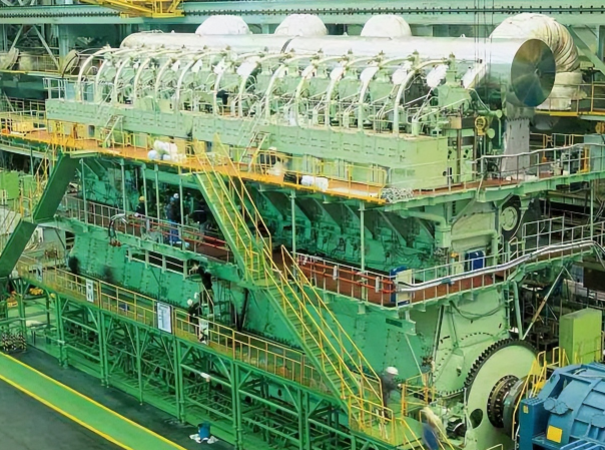

For large industrial and marine-type engines, the use of a spring starter and assisted start devices increases the total power used in the engine, which will reduce the starter motor load and the battery drain. However, low-speed and intermittent start principles should be observed.

Tips:

- Avoid prolonged continuous cranking to prevent starter overheating.

- Ensure proper fuel supply and that all air is purged to reduce black smoke or engine idling issues.

Step 5: Let the Engine Run and Stabilize

After the engine starts successfully, do not immediately apply heavy loads or run at high speed. Allow the engine to idle for a period to let all systems stabilize:

Monitor Key Indicators:

- Check that oil pressure is stable to ensure proper lubrication and avoid dry wear.

- Observe coolant temperature to confirm the cooling system is functioning correctly, preventing local overheating.

- Pay attention to exhaust emissions; if unusual smoke, odor, or irregular exhaust is observed, stop the engine immediately for inspection.

Ensure Fuel Supply is Stable:

Check that the fuel pump and injectors are working correctly. After long-term storage, fuel circulation may be sluggish; idling helps establish proper fuel flow and ensures reliable operation under load.

For Industrial Users:

For engines that have been idle for long periods, periodically start and run them briefly to maintain oil circulation and fuel flow, preventing component wear or degradation.

During idling, engine speed can be slightly increased, but sudden heavy loads or full-speed operation should be avoided to protect core engine components.

Tips:

The idling phase is critical for engine warm-up and self-check. Ensuring proper lubrication, fuel, and cooling circulation helps extend engine life and reduce failure risks.

Listen for unusual sounds or vibrations during this phase; stop the engine immediately if any abnormalities are detected.

Common Issues and Solutions When Starting a Diesel Engine Has Been Sitting

Diesel engines that have been sitting idle for extended periods can encounter several common issues that make starting difficult. Understanding these problems and their solutions is essential for anyone looking to learn how to start a diesel engine after long storage safely and efficiently.

Degraded Fuel

Problem: Diesel fuel can oxidize, absorb moisture, or develop sediment over time, leading to poor combustion and engine hard starting.

Solution: Replace the old diesel with fresh, high-quality fuel. Adding a fuel stabilizer or conditioner can help prevent future degradation and improve fuel longevity. Proper fuel management is a key step when learning how to start a diesel engine after long storage, as fuel quality directly affects ignition and performance.

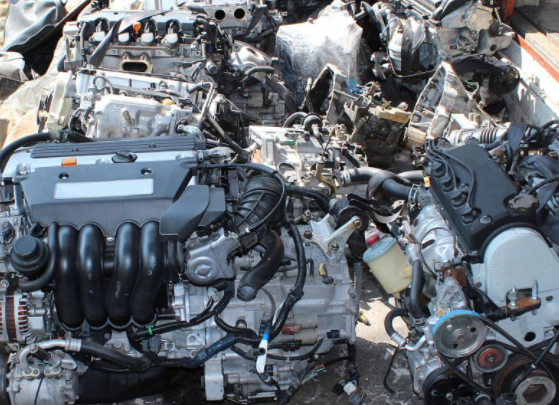

Excessive Carbon Deposits

Problem: The carbon may accumulate over time on an injector, combustion chamber, or valves, thereby hindering proper atomization of diesel and leading to improper combustion, thereby causing difficulty in starting an engine, rough idling, and black smoke.

Solution: Cleaning the fuel injectors and exercising common engine maintenance procedures like a carbon remover treatment service for the engine or an engine tune-up will definitely guarantee the smooth operation of even a long-idle engine. Familiarity with the procedures to start a diesel engine after long storage means becoming familiar with the procedures to prevent the buildup of carbon in the engine.

Low Battery Voltage

Problem: Batteries lose charge over time, and a weak or discharged battery may not provide enough power to turn the starter motor, especially for large diesel engines.

Solution: Charge the battery fully or replace it if it is old or damaged. For heavy-duty engines, consider using an assisted starting device such as a spring starter or other battery-powered starter to provide additional torque. Ensuring the battery is in good condition is a critical step in learning how to start a diesel engine after long storage, particularly in cold or industrial environments.

Air in Fuel Lines

Problem: During long periods of inactivity, it’s not uncommon for air to get into the fuel system, resulting in an engine that will crank over but will not start.

Solution: Adequate bleeding of the fuel system can be done through the use of a manual or electric-type fuel pump. The smooth flow of fuel to the injectors before initiating the engine can also be checked. Eliminating the presence of air is considered an important step in finding out the procedure for cranking the diesel engine after a few months of storage.

Tip: Regularly inspecting the fuel, battery, and engine components before storage can significantly reduce startup problems later. By addressing these common issues, you can ensure a smoother, safer, and more reliable start after long-term engine storage.

Tips for Preventing Problems That Diesel Engine Has Been Sitting

Proper storage and maintenance of a diesel engine can significantly reduce starting difficulties and extend the engine’s service life. Here are some practical techniques to prevent common issues:

Use a Fuel Stabilizer

Diesel can degrade over time due to oxidation and moisture absorption, leading to poor combustion and startup problems. Adding a high-quality fuel stabilizer before storage helps maintain fuel quality, prevents sediment formation, and ensures that the engine can start reliably even after long periods of inactivity.

Regularly Start the Engine

Even short-term operation is beneficial. Periodically running the engine keeps the lubricating oil circulating, maintains fuel flow, and prevents internal components from drying out. This practice is especially important for industrial or marine diesel engines, where long periods of inactivity can accelerate wear and corrosion.

Keep the Battery Charged

A fully charged battery is also a guarantee to supply the required power to the starter motor. It must be noted that the battery should not be completely discharged while in storage. Use a trickle charger or battery maintainer, if required, for storage of the battery.

Regularly Check Engine Oil and Coolant

Before storing the unit, as well as every time the storage containers are inspected, it is important to ensure that there is enough oil in the engine and that it is in the right state, as well as the coolant, which will help prevent corrosion and overheating of the machine’s internal components. It is also important to change the oil and coolant before storage to extend the lifespan of the machine.

Pro Tips:

- Store the engine in a clean, dry environment to prevent moisture-related issues.

- Label fuel tanks and check for water accumulation or contamination periodically.

- Proper storage and routine maintenance dramatically reduce startup difficulties, enhance engine reliability, and prolong the lifespan of your diesel engine.

- By following these preventive measures, anyone looking to learn how to start a diesel engine after long storage can greatly reduce risks and ensure smoother, more reliable operation.

Conclusion

Starting a diesel engine which has been idle for long requires taking a series of steps that include inspection and maintenance, fuel bleeding, low-speed starting, and stabilization of the engine after ignition. Observing the required steps ensures not only the safe ignition of the idle engine but also increases the long service life of the diesel engine. In the case of industrial diesel engines or heavy usage, assisted devices like a Cqstart spring starter greatly increase the efficiency in the starting of the engines.

An engine with a long period of idling does not pose a challenge when it comes to the startup. By following the procedures in the above guide, you can easily take care of the startup problems while undertaking your normal upkeep and maintenance.