In remote mountain irrigation, sudden diesel water pump starter failures risk crop drought; ships at sea may drift due to main motor starter malfunctions, and construction heavy equipment halts—incurring high downtime costs, disrupting workflows, and wasting resources.

Traditional battery-dependent solutions have clear limits: dead batteries (from storage/low temps), no stable power for charging/replacement in remote areas, and costly regular battery maintenance/replacement.

Battery-free spring starters (mechanical, no batteries needed) excel here—solving these pain points with simple structures, low failure rates, and cold resistance, offering a reliable new option for diesel engines in harsh/special environments.

Part 1. Understanding How Diesel Motor Starters Function

To accurately understand the diesel motor starter’s failure, we need to comprehend its fundamental working principle. The primary function of a diesel motor starter is to change electric energy into mechanical energy to get the engine flywheel to rotate. This allows the engine to perform the four-cycle (intake, compression, power, and exhaust) sequence to accomplish a successful start.

The starter’s operation is quite simple. As the driver turns the ignition switch/ starter button, the battery powers the starter’s solenoid. Upon energizing the coil, a magnetic force is created, and the iron core is drawn and moved. This action completes the connection of the starter’s internal armature circuit and moves the drive gear to mesh with the engine flywheel’s ring gear.

The battery’s large current moves the armature shaft thereby rotating and driving the flywheel. The solenoid energizing sequence, at the command of the driver, turns the system off marking the engine start. The system complete the operation with the solenoid disengaging and the drive gear decoupling from the flywheel. The entire start up process is then complete.

Part 2. Top 5 Most Common Problems Diesel Motors Starters Encounter

The starters for diesel motors can sometimes fail for many reasons. Some failures can be due to battery issues, but they can be due to mechanical issues, installation issues, or electrical issues. Here is a list for you to aid troubleshooting of all diesel starters failures in order of most common, and battery related and battery independent failures.

Failure 1: Starter Does Not Crank. (Loose Wiring, Faulty Solenoid, Worn Brushes, Not Just a Dead Battery)

The most frequent explanation for this issue is a dead battery, but this problem has some other possibilities. Electrically, corroded or oxidized terminals that connect to the battery or loose wiring can stop the flow of electricity in the system even if the battery is charged, and the problem should be considered first. An ignition switch that is faulty or a relay that is damaged can stop the startup signal altogether. Mechanically, a solenoid that is faulty (the coils burn and they can’t make the iron core move) or brushes that are worn (losing commutator contact) disabled operation. Open or shorted armature windings and oxidized commutators make the issues worse. To troubleshoot, you first should check the battery, then the terminals, to clean and tighten them. If the connections are tight and the problem persists, solenoids, brushes, or armature should be replaced.

Failure 2: Spinning Without Engaging the Flywheel (Causes: Damaged Drive Gear, Worn Flywheel Ring Gear)

In this scenario, the armature spins independently and the drive gear does not mesh. This can happen due to damaged (worn, deformed teeth) or faulty one-way clutches (blocks torque) or worn flywheel ring gears (thinned/chipped, brittle when cold) which will hinder engagement. The fix: for worn gears, the starter should be removed to replace the gear assembly, and overworn flywheel ring gears should be inspected and replaced. Also, check for proper spacing during installation.

Failure 3: Intermittent Starting (Causes: Poor Switch Contact, Corroded Terminals)

Difficult to troubleshoot, failure due to poor contact occurs when oxidized/burned switch/relay contacts (which is an increase in the contact resistance) cause an intermittent connection. Little corrosion or loose terminals can stabilize the current which can be worsened by any of the following: vibration, temperature changes, or atmospheric pressure changes. Troubleshooting: gauge switch/relay (replace if resistance is too high); clean and retighten terminals with sandpaper , apply an anti-rust agent, and check brush-commutator contact (replace brushes and/or polish commutator if needed).

Failure 4: Cold Weather Fuel Issues (Causes: Cold Weather Engine Oil and Friction Positives. Batteries Alone, Do Not Solve Problem)

Bottom 10 cold Celsius, even new batteries will struggle. The cold literally stacks the engine oil, and so high friction. The enhanced resistance of the armature (starter motor) will also result in its diminished power. Poor lubrication of the starter motor and frozen grease will worsen the sluggish solenoid and its movement. Then spring starters, that do not need batteries, will solve the cold because their cold torque will not be affected. Engine preheating will also help. Cold weather engine grease will also work.

Failure 5: Overheating or Unusual Noises (Causes: Unreliable Internal Mechanisms And Their Unreliable Alignments)

Overheating signals damage—from worn bearings, bent armatures (causing friction), poor gear meshing, or electrical issues (short-circuited windings, burned contacts). Frequent startups trap heat. Abnormal noises (buzzing from worn bearings, scraping from bent armatures, clicking from damaged gears) indicate mechanical problems. Misalignment (loose bolts) causes vibration. Troubleshooting: Stop using overheated starters; cool and inspect for issues. Identify noise sources, disassemble to replace faulty parts, and ensure proper installation.

Part 3. Effective Battery-Free Spring Starters Solutions

Facing various diesel motor starter failures—especially dead batteries, power-free environments, and cold-weather startup difficulties—battery-free solutions offer unique advantages. Below, we highlight the spring starter as the core battery-free alternative, along with other practical mechanical troubleshooting methods to help users resolve issues quickly.

Spring Starters–The Ultimate Battery-Free Replacement

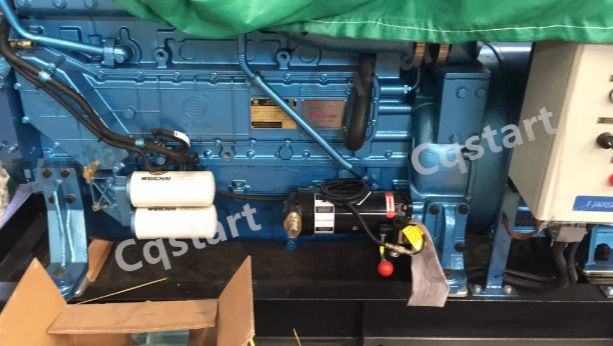

A spring starter is a mechanical starting device based on energy storage principles. It requires no battery, storing mechanical energy via manual winding and releasing it to drive the engine flywheel, enabling battery-free startup. It effectively addresses the battery dependency of traditional electric starters and boasts key advantages for diesel engines, making it ideal for special scenarios.

Core Advantages for Diesel Motor Engines

- No Need for Batteries or Cables: Battery dead? Not an issue. Diesel engines work and even start reliably while in dead, or deadweight, batteries, wires, and remote or wilderness locations, and with agricultural machinery for rugged mountainous areas and field exploration equipment or marine vessels.

- Exceptional Cold Resistance: Whereas electric starters and batteries are fiddling with their chains when it comes to low batteries and efficiency loss in cold climates, Diesel engines start cold and hot, providing constant torque from 40C cold to hot, wet humid areas. Diesel engine cold start torque is essential for outdoor winter equipment in the Canadian North.

- Mechanics are Simple, Low Failure: Being made of simple low tech mechanical systems consisting of springs, gears, housings, and simple handle to operate makes these systems and their makes balance and in rest of world to slavery remove the circuits and electronics, and their relies control circuit to slaves. Continue with blog then done it each for rely of gears simple with balance pass and load made of high alloy gears in rest of world.

- Operations Simple and No Nonsense Required: Users in any industry, train or just for fun crank or pull cord to start on engines, rest is engineered and dance to rely of gears and flywheel in systems while in transit of packed to start conditions then stop it, all to balance pass to start on any engine to balance and carve the control measurements.

Spring Starters Application Scenarios

The ability to function at extremes makes this useful in high reliability, complex condition scenarios.

- Agricultural Machinery: Used in tractors, harvesters, and irrigation pumps used in farmlands with limited power and in remote conditions with cold and humid weather.

- Marine Equipment: Used in small ships and fishing boats as a battery-friendly emergency start equipment at sea.

- Off-Grid Equipment: Used in field exploration tools, camping generators, and remote communicative base stations as a primary battery-less generator.

- Construction Machinery: Excavators, loaders and rollers use spring starters as backups for cold weather deterioration on mining and construction sites.

- Emergency Equipment: Firefighting generators and medical emergency equipment for quick start during battery failure and power outage.

- Bad Electric Starters: Spring starters complete the emergency of being stagnant while electric starters await repair and replacement.

Part 4. Installing a Spring Starter for Diesel Motor Engines

Overcoming hurdles is easy with a strategic approach and consistency on step processes with spring starters for diesel engines being no exception.

Pre-Installation Check

To avoid problems at the installation phase, confirm that the spring starter specs (voltage, torque, and mounting dimensions) are consistent with your diesel engine model. If not, mismatched components will the engine.

Tools Needed

Collect the simple tools needed: adjustable wrenches (removing fasteners), screwdrivers (flat and Phillips), and high-temperature lubricant (lubricating moving parts only during assembly for protection).

Installation Steps

To ensure safety, always disconnect the battery before removing the faulty electric starter by loosening its mounting bolts.

- With the spring starter, check the alignment with the engine’s mounting holes, and drive gear must smoothly align with the flywheel’s ring gear.

- Use the provided fasteners. Firmly and consistently tighten all bolts.

- Moving parts must be lubricated.

- For the operations test, manually crank the spring, and press the release. Check if the engine cranks by engaging the gear with the flywheel.

Summary

Diesel motor starter failures are usually the result of dead batteries, cold weather, or mechanical wear—fixes using batteries are often just as ineffective as the failures themselves. Cold-resilient, simplistic, and low maintenance spring starters are also spring starters and great battery-free alternatives.

Cqstart Spring Starters are great for any environment and emergency due to their ability to mitigate battery spring failures. With the right solution, reliable and consistent starting of diesel engines, and avoiding downtime, can be achieved.