In situations such as power outages, remote construction sites, emergency rescue operations, or when the electric starting system fails, knowing how to manually start generator becomes a critical skill for many users. The good news is that with the right method, a generator can still be started smoothly, even without a battery or external power supply.

Today, we will provide a systematic and practical guide to manually starting an engine, helping you get your generator up and running quickly and safely when it matters most. Let’s take a closer look.

Part 1. What is Manual Generator Start?

Manual generator start is essentially starting up a generator without using a battery or electric starter motor. In such a method, the engine is started by mechanically turning the crankshaft, hence enabling ignition or compression ignition, depending on the type of engine, gasoline or diesel.

The mode of starting this engine is particularly useful in conditions where power supply is not available, the batteries have run out, or an electric starting system is not functional.

Common manual starting methods include:

- Recoil Starter: Pull-cord starter that revs up the engine quickly. Usually used in portable generators.

- Hand Crank/Flywheel Start: This requires manual turning of the crank handle or flywheel in order to develop enough speed to ignite.

- Spring Starter: Stores energy in the spring and releases it instantaneously to turn the engine crank. It is ideal for diesel engines and adverse climatic conditions.

Compared to electric start mechanisms, manual start mechanisms have simpler configurations and less electrical content and failures. This is especially true for critical backup power systems that require reliability in emergency situations.

Part 2. How to Start Generator Manually?

Pre-Start Safety Checks for Manual Generator Start

Before attempting to start a generator, safety checks need to be done. This will not only ensure a successful start-up procedure, it will also ensure that the safety of the operator as well as the reliability of the generator remain optimal.

Firstly, make sure the fuel tank is filled to a sufficient level and the fuel valve is turned to the “ON position.” The engine oil should also be checked, as a lack of oil could cause the low oil protective system to trigger and thus hinder engine startup.

Next, it is important to remove the external loads before the startup process. It will help in reducing the startup resistance. Again, the generator must be located in a well-ventilated area. It should never be started in an enclosed or ill-ventilated area as it may cause carbon monoxide poisoning.

Lastly, check all control switches to ensure they are in the correct position. The choke should be placed in the start position, and the throttle should be in low speed or the start position.

Method 1: Recoil Starter (Pull-Cord Start)

The recoil starter, also known as the “pull-cord starter,” is the most popular type of manual start system. The recoil starter is widely used on small gasoline and diesel power generators because it is very easy to use and reliable.

Step-by-Step Operation:

Step 1. Disconnect all electrical loads: This involves making sure that all the loads connected to the generator are unplugged. This helps in cutting down the resistance in the engine.

Step 2. Open the fuel valve: Make sure fuel can flow to the carburetor or injection system.

Step 3. Set the choke to the start position: Adjust the choke to allow the proper air-fuel mixture for cold-starting the engine.

Step 4. Pull the starter rope slowly until resistance is felt: Gently pull out the cord until you feel the initial resistance, which indicates the engine is ready to rotate.

Step 5. Pull the rope with a firm, steady motion: Apply smooth, controlled force to rotate the crankshaft and initiate combustion. Avoid jerky or rapid movements.

Step 6. Adjust the choke gradually after the engine starts: Once the engine fires up, slowly move the choke back to the “run” position to ensure smooth operation.

Step 7. Allow the engine to warm up before connecting loads: Let the generator run for a short period to stabilize temperature and oil circulation before powering any equipment.

Precautions:

- Avoid pulling the cord violently, as this may damage the recoil mechanism.

- If the engine does not start after 3–5 attempts, check the fuel supply, spark plug, or ignition system to ensure proper functioning.

- While the process works easily for scaled-down versions of the generators, it does require some physical effort and technical skill to carry out the startup of the machine.

Method 2: Starting Manually When Battery Fails

Some generators may be equipped with an electric start system, but in situations where the battery is dead or compromised, one can make use of the mechanical start that comes with the machine. Such machines include diesel generators and other industrial or agricultural equipment.

Applicable to:

- Certain diesel generators

- Industrial machinery and agricultural equipment

Step-by-Step Operation:

Step 1. Engage the decompression lever: This reduces cylinder compression, making it easier to rotate the crankshaft and start the engine.

Step 2. Use the hand crank or flywheel to rotate the engine: Apply steady, controlled force to turn the crankshaft. The goal is to achieve sufficient rotational speed for the engine to ignite or compress-fuel start.

Step 3. Coordinate with engine timing and resistance: Experienced operators can feel the “kick” point when the engine is ready to start, allowing smoother ignition.

Notes and Considerations:

- Compared with a pull-cord starter, this type of starter requires stronger muscles and more skill.

- Great care must be taken to prevent engine kickback. This may result from rotating the crank too quickly or in an unbalanced manner.

- Though it requires a higher level of skills, this method is very useful in off-grid or no power settings, such that even in the absence of electricity, one is able to start the generator.

The method is basically a secondary option for a failed electric start and is reliable for more secluded or emergency situations, but is largely dependent upon the experiences and skills of the operator.

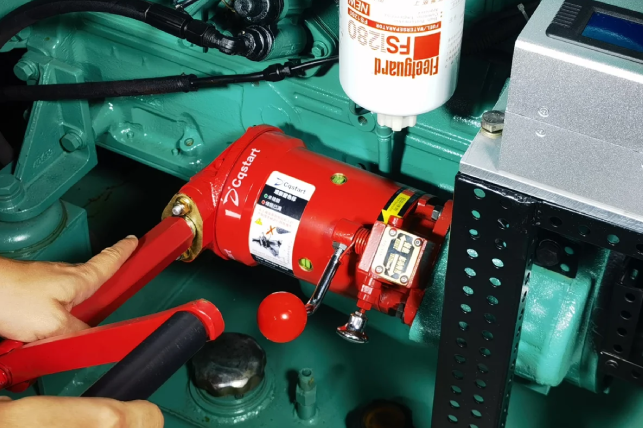

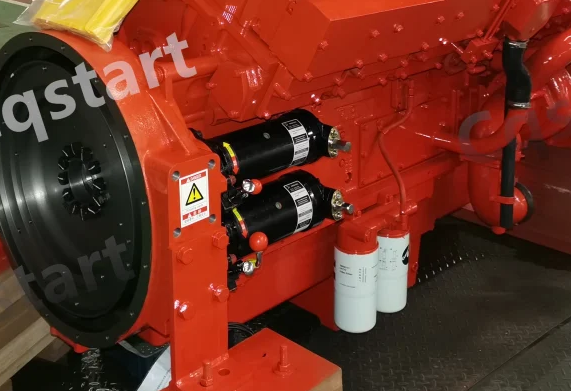

Method 3: Spring Starter for Diesel Generators

For diesel generators with high compression ratios and significant starting resistance, a spring starter provides a more efficient, safe, and reliable manual starting method compared with pull-cord or hand-crank systems.

Working Principle:

- Manually store energy in the spring: The spring is wound by the operator to store mechanical energy in advance.

- Release the spring: On release, the spring releases the stored energy quickly and provides high torques to the crankshaft.

- Crankshaft rotates at high speed: This helps in gaining the speed needed for the start of the engine, either through spark ignition or compression ignition.

Key Advantages:

- Does not require batteries or external power: Perfect for off-grid or emergency power.

- Stable startup torque and high success rate: Helps eliminate failed startups associated with inconsistent operator torque input.

- Resistant to extreme conditions: Capable of operating well in low-temperature, high-moisture, or isolated sites.

- Reduces physical efforts: The operator does not require applying constant efforts as in the case of a hand-crank or pull-cord operations.

Typical Applications:

- Diesel generators in industrial, remote, or emergency setups

- Fire pumps and water pumps requiring rapid deployment

- Marine equipment and emergency power systems

This method combines mechanical reliability with operator convenience, making it the preferred manual solution for large diesel engines starting or critical power systems where both safety and efficiency are priorities.

| Feature | Recoil Starter (Pull-Cord) | Manual Start When Battery Fails (Hand Crank / Flywheel) | Spring Starter |

| How It Works | Pulling a rope directly rotates the crankshaft | Hand crank or flywheel rotates the crankshaft, often with a decompression lever | Preloaded spring releases high torque to spin the crankshaft |

| Best For | Small gasoline or diesel generators | Diesel generators, industrial or agricultural equipment | High-compression diesel generators, fire pumps, marine and emergency systems |

| Difficulty | Low to moderate | Moderate to high; requires experience | Low; spring does most of the work |

| Success Rate | Medium | Medium to high | High |

| Physical Effort | Medium | High | Low |

| Safety | Medium; watch for rope recoil | Moderate; risk of crank kickback | High; torque release is stable |

| Advantages | Simple, low maintenance | Works without battery | Reliable, stable, easy to operate |

| Disadvantages | Requires effort and technique | Needs skill and strength | Slightly more complex; suited for specific equipment |

Part 3. Common Issues and Troubleshooting for Manual Generator Start

When manually starting a generator, several common problems may be encountered by operators. Knowledge of the cause and remedy helps in the safe and reliable operation of generators.

1. Pull-Cord is Hard to Pull

Possible Causes: A generator that is still under load, carbon buildup of the engine, or internal mechanical sticking of the engine.

Troubleshooting: Disconnect all electrical loads before entering. Check that the engine is free from carbon buildup or any other signs of internal binding; clean or service as required.

2. Engine Turns but Fails to Start

Possible Causes: Fuel quality issues, problems in the injection or ignition system, or clogged fuel lines.

Troubleshooting: Check that the fuel is fresh and uncontaminated. Inspect the spark plug (for gasoline engines) or injection system (for diesel engines), and ensure all connections are secure.

3. Backfiring During Start

Possible Causes: Incorrect choke position or abnormal ignition timing.

Troubleshooting: Adjust the choke to the proper start position and verify ignition timing according to the manufacturer’s specifications.

4. Repeated Start Failures

Precaution: Avoid further attempts to start the generator to prevent damage to the engine or the starter mechanism.

Troubleshooting: Before making another start, do an overall check of the system covering fuels, ignition, and mechanics.

The following troubleshooting procedures could, conceivably, resolve most operational problems related to manual starting of a generator.

Part 4. When to Choose a Manual or Spring Starter for Generator

Basic Rule of Thumb: manual or spring-start generators are perfect when you need reliability and independence from any outer source of power more than comfort. You should opt for these starting methods in cases of:

Remote or Off-Grid Environments: Locations without easy access to electricity or replacement batteries benefit from manual or spring-start systems, ensuring that the generator can be started anytime.

Emergency Backup Power: For critical applications such as emergency lighting, medical equipment, or rescue operations, having a manual or spring-start option provides a reliable fallback when electric start fails.

Cold or Harsh Conditions: Extreme temperatures, high humidity, or dusty and dirty environments can affect battery performance and electric starters. Manual or spring-start systems are less affected by these conditions.

High Reliability Requirements: If the operation prioritizes consistent startup success over convenience, manual methods offer a simpler, lower-failure-rate alternative.

Among these options, the spring starter is particularly suitable for diesel generators. It gives high startup torque, a high success rate, as well as plenty of reduction in the physical exertion of the operator when compared to the pull-cord or manual cranking methods. These features make it a very ideal component in large engines.

Cqstart Spring Starter: Reliable Choice for Starting Generator Easily

Being a company with nearly 20 years of experience in the production of spring starters, Cqstart has been concentrating on manual starting technology. Whatever the application, emergency power supplies, remote areas, potentially explosive zones, or industrial or marine installations, the spring starters developed by Cqstart make it easy to start a diesel generator set safely and reliably.