The most probable reason when a diesel engine does not turn over is: no power. Dead batteries, faulted wiring, or total lack of electric supply can bring essential machines to a standstill. In case of industries, which are situated far from the grid— or under very harsh conditions— this situation is more than a hassle. It can lead to costly downtime, risk to safety, and missed deadlines.

Thus, a very basic question keeps on popping up in the searches:

Is it possible to start a diesel engine without power?

The quick answer is yes— but only if the correct method of starting has been chosen. One of the solutions that have proved to be effective is the Spring Starter, which is an entirely mechanical device that can start diesel engines without the use of electricity.

Part 1. Can a Diesel Engine Start Without Power?

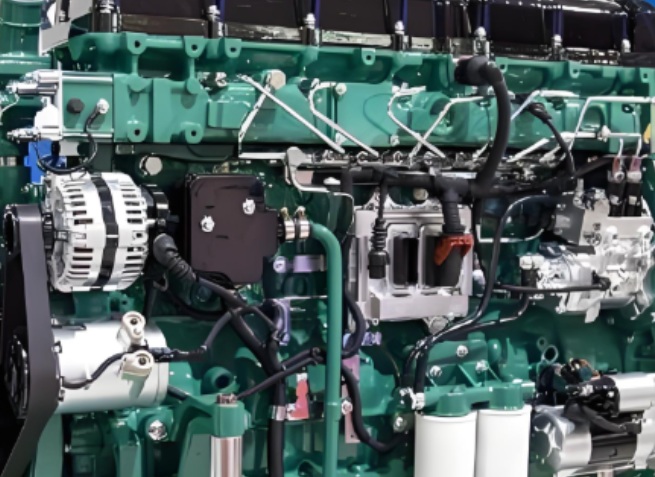

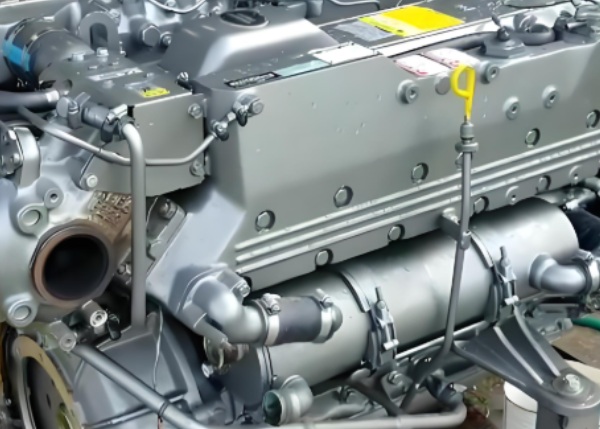

Diesel engines are not dependent on ignition, which already gives them a lower power situation compared to gasoline engines. Still, in most diesel engines, electricity is needed to rotate the engine through an electric starter motor. The absence of power means the starter will not turn at all.

Under real-world circumstances, power failure is a usual occurrence:

- Cold weather causes batteries to lose charge

- Corrosion of electrical systems occurs in humid or marine areas

- Unreliable charging infrastructure at remote locations

Operators are left to face a very difficult situation: a fully operational engine that can’t be started.

This is the point when the notion of power-free diesel starting becomes essential—and when spring starters appear in the scenario as a possible solution.

Part 2. Why Power-Free Diesel Starting Matters?

Loss of Power Is a Situation That Happens Often

According to the search data, there is a great demand for backup starting solutions because power failure is not merely a scenario that could happen but rather a routine practice in various industries.

Typical Situations Without Power

Manufacturing with Heavy Machinery and Mining at Remote Sites

Heavy machines are often used in places that are a long way from electrical supply. Maintaining and replacing batteries require many hours or even days.

Oil&Gas Fields and Offshore Platforms

Batteries die faster due to saltwater corrosion and bad weather. The cost and risk of fixing electrical faults offshore are very high.

Fire Protection Generators and Firefighting Equipment

Standby systems are meant to function during the total blackout. If the generator fails to start because of a flat battery, the repercussions might be grave.

Battery-Dependent Starters Have Their Limitations

Electric starters may be quite handy, but they have their drawbacks:

- Batteries lose their charge eventually

- Low temperatures can drastically affect the ability to crank the engine over

- It can be difficult to locate electrical faults in an outdoor setting

When the failure to start causes the idle time, safety issues or closing of the emergency response windows, the price of not starting is way higher than that of the reliable alternative.

Part 3. Can a Spring Starter Really Help Without Power?

This is the main question asked with the search query and the answer is dependent on some factors like reliability, independence, and practicality.

Real Power Independence

Spring starter does not need batteries, alternators, or outside electricity as a source. It instead uses a heavy-duty spring to store the mechanical energy which is released to crank the engine.

Cables free. No voltage. No charging.

Starting Reliability

The fact that spring starters are purely mechanical, allows them to:

- Not be affected by the low temperatures

- Work uniformly in wet, dusty, or corrosive environments

- Totally eliminate electrical failure points

In no-power situations, the simplicity of mechanics is an advantage.

Starting Performance and Stability

A properly sized and maintained spring starter provides high-torque cranking energy that is repeatable. Hence it fits very well to medium-sized diesel engines in industrial and emergency applications.

Operator Skill Requirements

A spring starter requires manual or mechanical pre-winding which is not an advanced technical skill. It may be a little hard but operators can safely and effectively start engines without electrical support with little training.

Part 4. Where Spring Starters Are Most Useful?

The use of spring starters does not mean that electric starters are to be phased out completely. They are the most dependable in certain regions with high-risk factors where the supply of electricity is not stable.

Remote and Off-Grid Locations

With off-grid locations, the more straightforward the arrangement, the more reliable the system will be.

- No charging stations are necessary

- Minimum Maintenance

- Perfect for remote pumps, compressors, and generators

Spring starters keep the engines working even when there is limited support from the logistics side.

Emergency and Standby Equipment

Emergency devices must start right away, not after some electrical issues have been resolved.

Applications are typically as follows:

- Emergency diesel generators

- Fire fighting pumps

- Rescue and disaster-response equipment

In such situations, spring starters are very often installed as the first or second backup starting systems to ensure that the machines are ready to work when they are most needed.

Harsh and Extreme Environments

Batteries have a bad reputation of being very choosy with the following environmental factors:

- Extremes in temperature

- Highly humid conditions

- Dust and vibration

Spring starters are highly reliable in the following situations:

- Arctic or high-altitude regions

- Tropical and marine climates

- Mining and desert conditions

Since there are no electronic parts, performance remains unaffected even under very harsh environmental conditions.

Part 5. Is a Spring Starter the Right Solution for You?

There is no need for a spring starter for every engine. The right solution is to identify the case in which the spring starter works best.

Quick Yes / No Checklist

| Decision Factors | Scenarios/Requirements | Is a Spring Starter the Right Solution? |

| Power Dependence | Your engine has to start even without electricity | ✅Yes |

| Operating Environment | The machine works in wild or very cold places | ✅Yes |

| Usage Frequency | The engine is occasionally used or only for emergencies | ✅Yes |

| Core Priority | Reliability is given more priority than the convenience of use | ✅Yes |

| Usage Frequency | Engine starts several times in a day | ❌No |

| Power Availability | There is always electrical power available | ❌No |

| Automation Need | Automation is needed with no possibility of human intervention | ❌No |

Primary Starter or Backup System?

Many operators opt for a dual-start configuration that consists of:

- Using an electric starter during normal operation

- A spring starter is the power failure backup

This method suits both convenience and resilience and is widely accepted in critical industries.

Cost vs. Risk Consideration

The upfront cost of a spring starter may be greater than that of a regular electric starter, but its worth becomes apparent once the following are taken into account:

- No downtime

- Less maintenance

- No emergency breakdowns

In high-risk areas, the return on investment in reliability is frequently significant.

Summary

So, can a spring starter really help when starting a diesel engine without power?

Absolutely—when reliability is the critical factor over convenience.

Spring starters provide a mechanical solution that has been tested and proven for the situations where the electrical systems have failed or are not available. Their non-dependence on batteries, their toughness during the extreme conditions, and their reliable starting performance undoubtedly make them more useful in remote, emergency, and difficult places where electrical systems are unavailable or unreliable.

They are not an automatic substitute for electric starters, but in some applications, they are just the opposite: irreplaceable.

If your business really relies on diesel engines that have to start under any circumstances, installing Cqstart spring starter can be the most secure and reliable protection that you can have.