The selection of the correct pump starter is among the most crucial decisions to make to ensure the smooth and secure operating of the pump. Whether the pump is being used for irrigation in agriculture industrial processes, diesel-powered pump, marine pumps and emergency system, type of starter will determine how quickly and safely the pump can be put to operation.

A lot of users ask: Which pump starter is the most secure? Which one is the easiest to use? Should I go with an automatic system or use the manual method? Is there an alternative to remote-location or diesel pumps?

The differences between automatic and manual pump starters will assist in choosing the right starter for your needs and prevent possible future downtimes and irregularities in the pump’s operations.

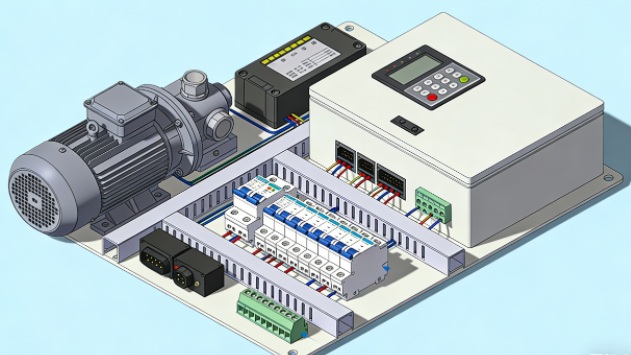

Part 1. Understanding Automatic Pump Starters

A pump starter that is automatic is a device for controlling the way a pump can start and stop a pump with no human intervention. It is able to monitor conditions in the system, like water level or pressure. It then automatically activates the pump if required.

Common automatic pump systems include:

- Float switches for water level control

- Pressure controllers for household water boosters

- Electronic pump controllers for irrigation

- PLC or relay-based industrial pump automation

When the system notices that water pressure is dropping or increases to a certain level then the automatic starter starts the motor. If the demand ceases the pump automatically shuts down the pump.

Automatic pump starters are widely used in:

- Home water supply systems

- Booster pump systems

- Irrigation systems

- Industrial automated processes

Advantages of Automatic Pump Starters

- Fully automated operation-No manual involvement is required. The system starts and stops on its own.

- Ideal for frequent start-stop cycles-Automated control handles repetitive tasks efficiently.

- Compatible with smart systems-Works well with sensors, controllers, and monitoring systems.

Limitations of Automatic Pump Starters

- Dependence on electricity-Automatic starters can’t operate without a stable power source.

- Higher maintenance requirements-Electronic parts, sensors and wiring all require periodic maintenance.

- Not recommended for hazardous or explosively prone environments – Electrical components are a risk when used in oil and gas fields or in marine engine rooms.

These limitations mean that while automatic starters are convenient, they may not be the best choice for all pump applications–especially for diesel-driven pumps or remote locations.

Part 2. Understanding Manual Pump Starters

The manual starter for a pump requires that the user start the engine or pump physically. Manual starters are typically employed on smaller diesel or gasoline engines and in places in which electricity is scarce or not available.

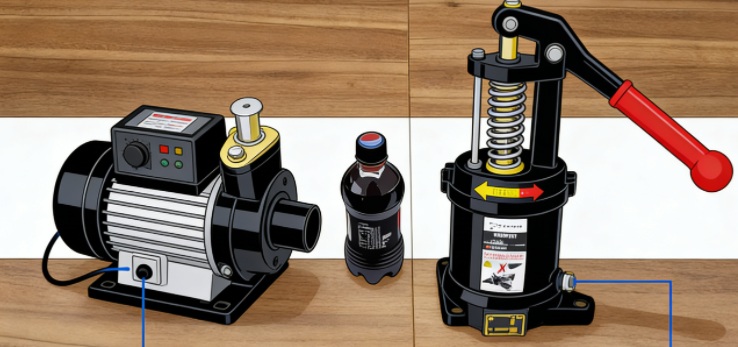

Manual starters are typically available in three varieties:

- Spring Starter (mechanical spring-based starter) A battery-free, mechanical device that stores spring energy to begin the engine of the pump.

- A pull-start (recoil starter) uses an engine cranking mechanism that is a rope. the engine.

- Start the engine with crank (hand-crank mechanism) A person hands-on turns the crank handle in order to start the engine.

Of these among them, one of them is the Spring Starter has become increasingly popular because of its safety in its reliability, dependability, and simplicity of use.

Benefits of manual pump starters

- No electrical power needed – Perfect for areas that are off grid or remote.

- Simple design and minimal maintenance – Mechanical systems are by nature more durable.

- Reliable in emergencies – A manual system is functional regardless of whether batteries or power fail.

Limitations of manual pump starters

- Requires physical exertion – Pull-start or crank system can become exhausting and challenging for some users.

- Less practical than automated systems – Manual intervention is necessary every time the pump has to operate.

These issues are drastically reduced, or completely eliminated when using a spring that is mechanical starter.

Automatic vs Manual Pump Starter: Key Differences at a Glance

| Difference | Automatic Pump Starter | Manual / Spring Starter |

| Power Source | Requires electricity | No electricity needed |

| Ease of Use | Fully automated | Depends on design; Spring Starter is easy |

| Reliability | Sensitive to electronic failure | Highly reliable mechanical design |

| Maintenance | Higher | Very low |

| Best For | Home & automated systems | Diesel pumps, remote sites, emergency use |

This simple comparison shows that while automatic starters are ideal for convenience, manual systems—especially Spring Starters—excel in reliability and off-grid performance.

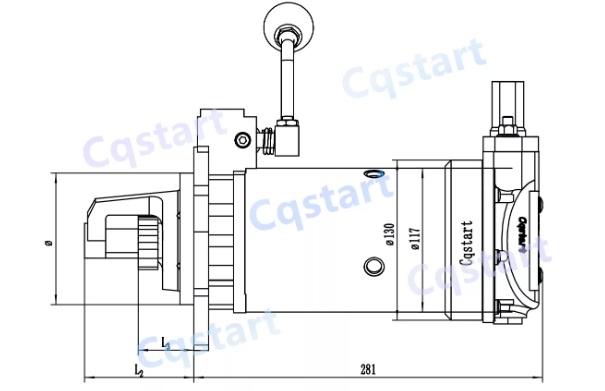

Part 3. Why the Spring Starter Is the Better Manual Start Option?

The Spring Starter is a specialized mechanical starting system designed to start diesel engines without a battery, electricity, or external power. It operates by manually winding a spring to store energy. When released, the stored mechanical energy cranks the engine with high torque.

Key Benefits of Spring Starters

1. Safer and easier than rope or crank start

Compared to traditional manual starters:

- No kickback or reverse rotation

- No heavy pulling or cranking required

- Smooth, controlled operation

This makes it ideal for pumps used by workers who may not have the strength for rope starts.

2. High torque output for diesel pump engines

Diesel engines require significantly more starting torque than gasoline engines. A spring starter can deliver powerful, consistent cranking that pull-start or crank-start systems cannot match.

3. 100% battery-free and electricity-free

Perfect for:

- Remote agricultural pumping sites

- Offshore and marine pumps

- Oil & gas field pumps

- Emergency and firefighting pumps

You never have to worry about a dead battery, wiring failure, or generator issues.

4. Durable, low-maintenance mechanical design

Spring starters have no electronics, no wiring, and almost no consumable parts. They can operate in:

- Wet environments

- Dusty conditions

- High-vibration applications

- Hazardous or explosive areas (ATEX-safe)

This reliability is a major advantage over electric starters and automatic systems.

Part 4. Which Pump Starter Should You Choose? (Scenario Guide)

Here is a quick guide to help you select the right starter:

Choose Automatic Pump Starter if:

- You have a household or commercial water system

- You want hands-free, fully automated pump operation

- Electricity is stable and maintenance staff is available

- You require integration with sensors or smart controls

Choose Manual or Spring Starter if:

- Your pump is driven by a diesel engine

- You operate in off-grid, rural, marine, or industrial locations

- Reliability is more important than automation

- You need a safe, battery-free solution

- You’re using pumps for firefighting or other emergency purposes

In general:

- Automatic starter = Convenience

- Spring starter = Reliability + Safety + Independence from power

Conclusion

Both manual and automated pump starters have advantages, and the most appropriate option will depend on the specifics of your needs. Automated starters are great for automated and household systems where ease of use is crucial. For diesel engine pumps remote environments, marine applications and emergency systems the Spring Starter stands out as an easier, safer and maintenance-free option. Understanding how each type operates, and the areas where each is superior, you will ensure that your pump will last for a long time to be.