Engineers working in high-risk industries such as heavy equipment, marine engineering, and oil and gas fields face an urgent task of quickly and reliably starting diesel engines on demand. Air starters have proven to be a superior choice due to their high torque output, explosion proof capabilities, and low maintenance needs compared to alternative options.

As application scenarios continue to vary, alternative solutions like spring starters have gained more and more attention.

Today, we will provide detailed information on air starter for diesel engine, compared to other starting methods, to help you choose the best starting solution for your diesel engine.

Part 1. What is an Air Starter?

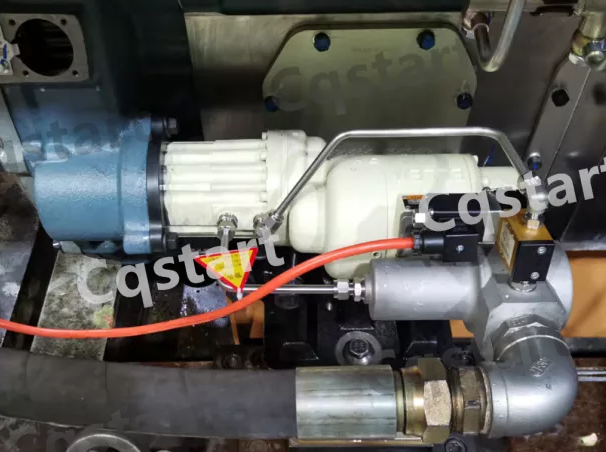

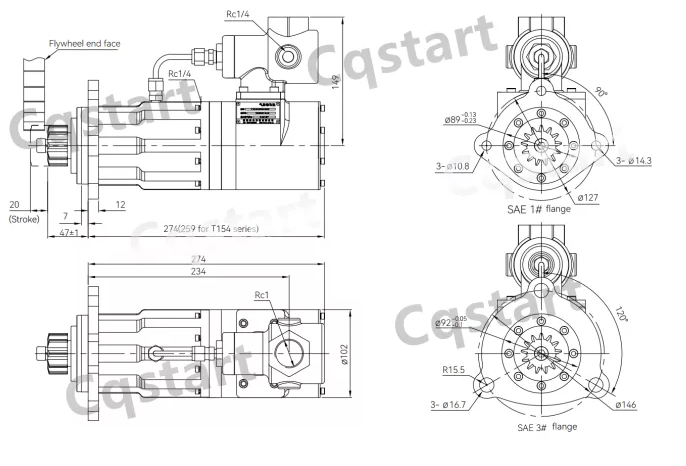

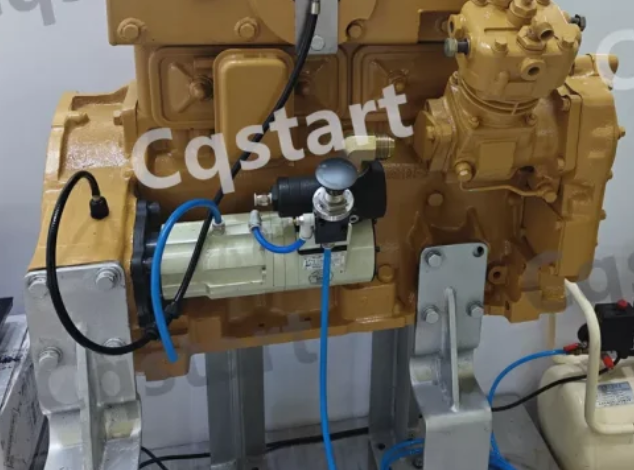

An air starter is a device that utilizes compressed air as its power source to start up a diesel engine. Instead of relying on electricity or batteries, the system uses high-pressure air stored in tanks to power a small turbine or vane motor, which then engages with the engine’s flywheel and spins rapidly enough to initiate combustion processes and start up the engine.

Key Advantages of Air Starters:

Independent of Electrical Power:

Air starters operate entirely without batteries or electric current, making them ideal for harsh, remote, or power-restricted environments such as offshore platforms, desert oil rigs, and mining operations.

High Starting Torque:

Air starters deliver powerful torque output, enabling them to crank large displacement diesel engines that require significant force to turn over—especially in cold or high-resistance conditions.

Explosion-Proof & Safe in Hazardous Environments:

Since no electrical spark is involved in the starting process, air starters are intrinsically safe. This makes them well-suited for flammable or explosive settings, including mines, oil refineries, petrochemical plants, and marine vessels operating in volatile atmospheres.

Compact & Lightweight Design:

Many air starters are smaller and lighter than electric starters of comparable power, which helps reduce overall equipment weight and simplifies installation.

Low Maintenance:

With fewer moving parts and no reliance on electrical systems, air starters generally require less frequent maintenance, improving equipment uptime and reducing long-term costs.

Part 2. How Does an Air Starter Work?

Air starters employ high-pressure compressed air to begin turning a diesel engine’s flywheel. Their design emphasizes simplicity, safety and effectiveness – especially in environments where electrical systems may pose risks or be unavailable.

Working Principle Step-by-Step:

Compressed Air Supply:

To begin the process, compressed air must first be stored in tanks at 90-150 psi (6 to 10 bar). When an operator begins the start sequence (whether manually or automatically), a start valve opens to allow compressed air into the air starter unit.

Starter Motor Accumulates Air:

Pressurized air is channeled through an air starter to an air motor containing vane or turbine-type motor, which converts its energy into mechanical rotational motion.

Flywheel Engagement:

As compressed air passes through, it drives the rotor or turbine blades inside of a motor at high speeds, and this rotational energy is transferred via gear reduction systems to provide enough torque to start an engine.

Flywheel Engagement:

An air starter comes equipped with a Bendix or overrunning clutch mechanism to engage the engine’s flywheel ring gear and rotate its flywheel; in turn, this causes its crankshaft to spin quickly enough for combustion to begin.

As soon as the engine reaches its required cranking speed, fuel injection and ignition take over, and it starts running under its own power without the assistance of air starter. Once running on its own power, air starter is released automatically from its grip on the flywheel.

Air System Resets:

After startup, the air supply is shut off, and the remaining air is either vented or stored for the next start. The system then returns to standby mode, ready for the next startup cycle.

Part 3. Common Applications of Air Starters

Air starters play a critical role in industries where safety, reliability, and independence from electrical systems are essential. Their unique characteristics make them irreplaceable in the following demanding environments:

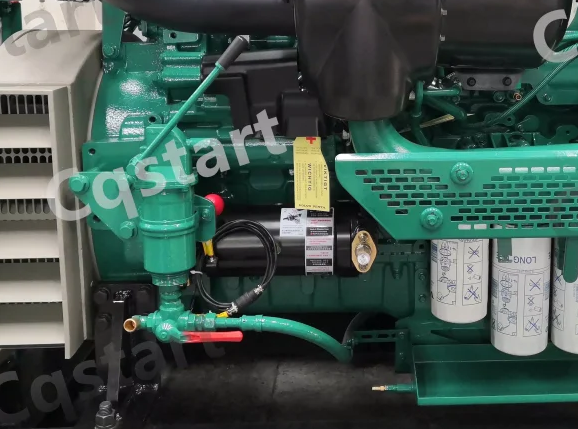

1. Marine Diesel Engines

In the marine industry, vessels such as cargo ships, offshore platforms, tugboats, and fishing vessels often operate in remote areas where electrical systems may be unreliable or affected by moisture and salt.

To ensure reliable engine ignition under such harsh conditions, air starting systems in marine diesel engines are widely adopted for their durability, safety, and independence from electrical power.

Why air starters are used:

- They are immune to corrosion and electrical short circuits.

- Offer high torque to crank large marine diesel engines.

- Comply with marine safety regulations, particularly for explosion-proof systems in engine rooms.

Typical application: Starting main propulsion engines, emergency generator sets, and auxiliary engines.

2. Oil and Gas Fields

Onshore and offshore oil rigs, drilling equipment, and gas compressor stations often operate in volatile environments with flammable gases.

Why air starters are used:

- No spark risk, ensuring intrinsic safety.

- Operate without electricity, ideal for remote oilfields or where batteries are unreliable.

- Provide consistent starting power for engines in harsh environments.

Typical application: Diesel-driven pumps, compressors, generators, and emergency backup engines.

3. Mining Equipment

Mining operations demand rugged, spark-free, and high-torque starting systems for equipment working deep underground or in dusty, explosive zones.

Why air starters are used:

- Explosion-proof for underground use.

- Can endure dust, vibration, and temperature extremes.

- No need for electrical wiring in hard-to-access equipment.

Typical application: Heavy-duty diesel engines in loaders, drills, haul trucks, and ventilation systems.

4. Backup Systems in Power Plants

Power generation facilities often use air starters for emergency diesel generators or turbines that must start instantly during blackouts.

Why air starters are used:

- Fast and reliable startup, even without external power.

- Keep critical systems running during grid failure.

- Avoids the delay and vulnerability of electric starters during emergencies.

Typical application: Emergency generators, fire pump engines, and critical backup systems.

5. Hazardous/Explosive Environments

Industries handling chemicals, fuels, or volatile substances must avoid any source of ignition.

Why air starters are used:

- They are intrinsically safe, as the pneumatic system generates no sparks or heat.

- Meet stringent ATEX or IECEx certifications for explosive atmospheres.

Typical application: Chemical processing plants, fuel terminals, and refineries.

Part 4. Comparison Air Starter vs Other Starting Methods

To help you better evaluate the best starting system for your diesel engine, let’s compare several common starting methods across key criteria such as power source, explosion safety, maintenance cost, and typical application environments:

| Starting Method | Power Source | Explosion-Proof | Maintenance Cost | Typical Applications |

| Air Starter | Compressed Air | ✅ Yes | Low | Oil fields, marine vessels, heavy machinery |

| Electric Starter | Battery/Electricity | ❌ No | Medium | Standard vehicles, light-duty equipment |

| Hydraulic Starter | Hydraulic System | ✅ Yes | High | Offshore platforms, military and specialty gear |

| Spring Starter | Manually Charged Spring | ✅ Yes | Very Low | Remote areas, emergency systems, low-infra setups |

Detailed Analysis of Each Type:

Air Starter

Strengths: High torque, no spark risk, durable in harsh conditions, low maintenance.

Weaknesses: Requires a compressed air system (tank, compressor, lines).

Best for: Environments where explosion protection and non-electric operation are essential.

Electric Starter

Strengths: Easy to use, compact, widely available.

Weaknesses: Battery-dependent, prone to failure in cold or damp environments, not explosion-proof.

Best for: Everyday vehicles, small generators, equipment in controlled environments.

Hydraulic Starter

Strengths: Very powerful, spark-free, suitable for extreme conditions.

Weaknesses: Complex setup, high maintenance, hydraulic fluid leakage risks.

Best for: High-stakes industrial and offshore operations, defense or marine sectors.

Spring Starter

Spring starters work by manually pre-winding a spring, storing mechanical energy that is later released to turn over the engine.

Strengths:

- No electricity or air required: works in complete isolation.

- No sparks, explosion-proof: suitable for hazardous environments.

- Extremely low maintenance: no fluids, batteries, or compressed systems.

- Lightweight and compact: ideal for space-constrained installations.

Best for:

- Remote areas with no access to electricity or compressed air.

- Emergency start systems where the engine must start reliably under all conditions.

- Application where simplicity, safety and independence are of the utmost importance, such as rescue pumps, emergency generators, mobile diesel units or standalone fire systems.

Though air starters remain the go-to solution in many industrial applications, spring starters have recently emerged as an affordable and low maintenance alternative. Determining which starter best meets your operational environment’s safety requirements and infrastructure availability.

Part 5. How Can You Select the Appropriate Starter for Your Diesel Engine?

Selecting an ideal starter is essential to ensuring your diesel engine performs reliably under all operating conditions, whether powering a marine generator, mining vehicle or emergency system. It must meet its specifications and working environment.

Here are the key considerations when selecting an ideal starter:

1. Engine Displacement and Power Output

The larger and more powerful a diesel engine is, the greater will be its torque requirements for cranking.

Make sure the starter can provide sufficient torque to overcome engine compression resistance.

Air and hydraulic starters are great choices for larger displacement engines, while spring starters make more sense in terms of space efficiency and simplicity.

2. Available Power Sources (Air, Electricity and Hydraulics)

To determine whether your working site can access compressed air, electricity or hydraulic systems.

If your compressed air source is reliable and maintenance costs remain manageable, an air starter is an effective and low-maintenance way to start it up.

Electric starters can be simple and cost-effective ways of starting up electrical systems, provided explosion-proofing requirements do not arise.

If there’s no steady power source, spring starters requiring no external energy input become an ideal alternative.

3. Installation Space and Environmental Conditions

Inspect the space constraints as well as external conditions like moisture, dust, vibrations or the presence of flammable gases before installing equipment in any given location.

For tight or hazardous spaces, opt for an explosion-proof starter (air or spring types).

When operating systems in harsh environments like offshore platforms, such as corrosion must be considered an elemental challenge that must be met head on with robust materials and coatings that can stand the test of time.

4. Maintenance Requirements and Operational Simplicity

Consider how often you can afford to maintain or service the starter system.

Spring starters require almost no maintenance, no fluids, no batteries, no moving air parts.

If maintenance teams or spare parts are hard to access, a low-maintenance, mechanical solution is ideal.

In automated systems, starters with remote control or automated recharging features (like some air and hydraulic models) may be preferred.

5. Start Frequency and Emergency Reliability

Some applications require frequent starts, while others demand 100% reliable emergency starts, even after long periods of inactivity.

For frequent starts, systems with quick recharge or multi-start capability are essential (air or electric starters).

For emergency or standby systems that may remain dormant for months, spring starters are ideal, as they do not degrade over time and can be pre-wound and stored in a ready-to-use state.

When to Choose a Spring Starter

If your equipment is:

- Located in remote areas without stable electricity or air supply,

- Part of a safety-critical emergency system where failure is not an option,

- Or needs a maintenance-free, spark-free, and lightweight starter,

Then a spring starter is a strong alternative. It offers mechanical reliability, full independence, and is especially effective for fire pumps, emergency generators, mobile diesel units, and military or disaster relief equipment.

In conclusion, selecting the right starter requires balancing technical needs, environmental factors, and operational constraints. Understanding these considerations ensures that your diesel engine starts safely, consistently, and efficiently—whenever and wherever it’s needed.

Conclusion: Choose the Right Starting Method for Your Application

Air starters have long been the standard solution for diesel engine ignition in industrial environments, thanks to their high torque, reliability, and explosion-proof performance. They are ideal for applications that have access to compressed air and require robust, safe starting systems, such as in the marine, mining, and oil & gas sectors.

However, not all scenarios are suitable for air systems. In remote locations, or where no electricity or compressed air is available—or in emergency and ultra-safe environments, the spring starter stands out as a more economical, simpler, and fully self-contained alternative. With zero reliance on external power sources, no spark risk, and virtually no maintenance, it is the preferred choice for backup engines, mobile units, and critical systems.

At Cqstart, we not only provide high-quality air starter solutions, but also specialize in the design and manufacturing of spring starters, delivering products that are reliable, durable, and maintenance-free.

Need help choosing the right starter for your diesel engine?

Feel free to contact Cqstart for professional technical support, detailed product catalogs, and tailored recommendations.

Whether you need a custom air starter or a spring starter for off-grid emergency use, Cqstart is here to provide end-to-end solutions that meet your toughest operational needs.