Diesel engines, with their high fuel efficiency, large torque, and long service life, are widely used in trucks, construction machinery, generator sets, ships, and other fields. However, even though they are structurally robust and performance-reliable, diesel engines still encounter various issues during operation. Understanding the symptoms, causes, and solutions to these common problems helps reduce maintenance costs and improve equipment efficiency.

Today we will provide a detailed explanation of several common diesel engine problems and preventive strategies, helping you quickly identify issues and minimize downtime.

Problem 1. Diesel Engine Fails to Start

A diesel engine failing to start is a common issue that can arise from various causes. Identifying the root cause quickly can help you take the right steps to resolve the problem and get the engine running again efficiently.

Common Causes:

Battery Drain or Decreased Performance: If the battery is weak or its capacity has diminished over time, it may not supply enough power to start the engine.

Starter Motor Failure: A faulty starter motor can prevent the engine from cranking properly.

Fuel Injection System Air or Blockage: Air in the fuel system or blockages can hinder proper fuel flow, affecting engine start-up.

Impure Fuel or Low External Temperatures: Contaminated fuel or extreme cold temperatures can cause the engine to fail to start, especially when fuel thickens or freezes.

Solutions:

Check and Replace the Battery: Ensure the battery voltage is normal and replace it if necessary.

Clean the Fuel Injectors and Fuel Lines: Remove any air or blockages in the system to restore proper fuel flow.

Use Quality Fuel and Preheat the Engine: Ensure the fuel is free of impurities and consider preheating the engine if temperatures are too low.

Professional Recommendation: Use a Spring Starter

For diesel equipment that operates in environments where relying on electrical power is difficult, or in harsh conditions, traditional electric-start systems have significant limitations.

In such cases, a spring starter is a reliable and economical solution. This mechanical starting device does not require a power source, is easy to maintain, and is highly effective.

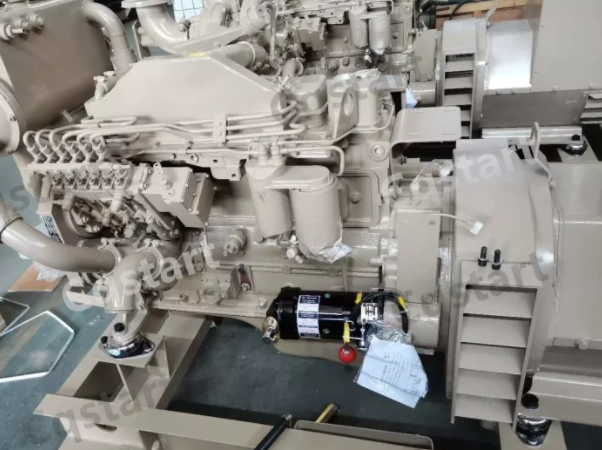

For instance, Cqstart Spring Starter utilizes a high-strength spring mechanism to store mechanical energy, which is then manually released to ignite the diesel engine. The product offers the following advantages:

- No Need for a Battery or Starter Motor: It operates independently of electrical power sources.

- Ideal for Power-Less Environments: Perfect for use in locations like mining areas, high altitudes, or offshore environments where electricity is scarce.

- Compatible with Major Diesel Engines: It is compatible with popular engine brands like Cummins, Perkins, Yanmar, Deutz and others.

- Compact Design, Easy Installation, Long Life: The spring starter is designed to be space-efficient, easy to install, and offers a long service life.

Cqstart Spring Starter has been widely used in emergency generator sets, marine engines, underground equipment, and other applications, helping users overcome the challenge of engine start-up in complex working conditions without relying on electrical power.

Problem 2. Diesel Engine Producing Black Smoke

Black smoke is one of the common issues diesel engines face, often signaling incomplete combustion. Let’s dive into the main causes and solutions for this problem.

Common Causes:

Clogged Air Filter, Insufficient Air Intake: A dirty or clogged air filter restricts airflow into the engine, leading to incomplete combustion and black smoke.

Excessive Fuel Injection or Poor Atomization: If too much fuel is injected or the fuel isn’t properly atomized (broken down into fine droplets), the engine burns fuel inefficiently, producing black smoke.

Impurities in Diesel Fuel or Turbocharger Damage: Contaminated fuel can cause poor combustion, and a malfunctioning turbocharger can fail to supply the necessary air pressure for optimal engine performance, resulting in black smoke.

Solutions:

Regularly Replace the Air Filter: Ensure the air filter is clean and replace it regularly to maintain proper airflow into the engine.

Adjust Fuel Injection Settings or Check Injectors: Properly adjust fuel injection timing and quantity to avoid excessive fuel delivery. Additionally, inspect the condition of fuel injectors to ensure efficient fuel atomization.

Check the Turbocharging System: Inspect the turbocharger for any faults or damage and ensure it is working properly to maintain the correct air pressure for combustion.

Problem 3. Diesel Engine Producing White Smoke

White smoke from a diesel engine often signals incomplete combustion or issues with the fuel system. Below, we’ll explore the common causes and practical solutions to address this problem effectively.

Common Causes:

Incomplete Combustion of Diesel: White smoke is often a result of incomplete combustion, where the fuel doesn’t burn fully, typically due to low engine temperature or improper fuel injection.

Incorrect Fuel Injection Timing: If the fuel injection timing is incorrect, fuel may be injected at the wrong moment, preventing it from burning efficiently and causing white smoke.

Cylinder Head Gasket Leak, Coolant Entering the Combustion Chamber: A leaking cylinder head gasket can allow coolant to mix with the fuel in the combustion chamber, resulting in white smoke due to the coolant burning along with the fuel.

Solutions:

Calibrate Fuel Injection Timing: Ensure the fuel injection timing is properly adjusted to optimize combustion and reduce white smoke. This may involve using diagnostic tools or consulting the engine’s manual for specifications.

Inspect the Fuel Injection System for Wear or Blockages: Check the injectors and fuel lines for any signs of wear or clogging, as faulty injectors can lead to improper fuel delivery and incomplete combustion.

Check for Leaks in the Cylinder Cooling System: Inspect the cylinder head and cooling system for any leaks that could allow coolant to enter the combustion chamber. A leaking head gasket should be replaced promptly to prevent further damage to the engine.

Problem 4. Diesel Engine Overheating Issue

Engine overheating is a serious problem that can lead to severe engine damage if not addressed promptly. In this section, we’ll look at the common causes of overheating and the best solutions to keep your engine running at optimal temperatures.

Common Causes:

Insufficient Coolant or Leaks: If the coolant level is low or there is a leak in the cooling system, the engine may not receive enough cooling, leading to overheating.

Water Pump or Thermostat Failure: The water pump circulates the coolant, and the thermostat regulates the engine temperature. If either of these components fails, the cooling system can’t operate efficiently, causing the engine to overheat.

Clogged Radiator or Damaged Fan: A dirty or clogged radiator restricts airflow, reducing its ability to cool the engine. A malfunctioning fan can also contribute to this problem by failing to provide the necessary airflow to the radiator.

Solutions:

Regularly Top Up Coolant and Inspect the System: Ensure the coolant level is sufficient and top it up as needed. Also, regularly check the cooling system for leaks in hoses, radiator, or other components.

Replace Worn-out Parts and Clean the Radiator: Over time, components like the water pump, thermostat, and radiator can wear out. Replace any aging or damaged parts, and clean the radiator to ensure proper heat dissipation.

Use Antifreeze to Prevent Scaling: In areas with hard water, the use of antifreeze is essential to prevent scale buildup in the cooling system, which can block coolant flow and lead to overheating.

Problem 5. Unusual Noise During Engine Startup

Hearing unusual noises when starting a diesel engine can indicate underlying issues that require attention. In this section, we’ll go over the common causes of such noises and how to address them to prevent further damage to the engine.

Common Causes:

Incorrect Fuel Injection Timing: If the fuel injection timing (injection advance) is not set correctly, it can cause improper combustion during startup, leading to knocking or other unusual noises.

Wear in Pistons, Connecting Rods, or Valves: Worn-out engine components such as pistons, connecting rods, or valves can cause mechanical noise during startup, as they fail to perform their intended function properly.

Severe Carbon Build-up in the Combustion Chamber: Excessive carbon deposits in the combustion chamber can interfere with normal engine operation, leading to knocking or rattling sounds during startup.

Solutions:

Adjust Fuel Injection Timing: Ensure the fuel injection timing is correctly calibrated to prevent abnormal combustion and reduce engine noise. This may require using diesel engine diagnostic tools or referring to the engine’s manual for specific settings.

Check Internal Mechanical Components for Wear: Regularly inspect the pistons, connecting rods, and valve components for signs of wear. If any components are found to be worn out or damaged, they should be replaced promptly to avoid further engine damage.

Clean Carbon Deposits from the Combustion Chamber: Over time, carbon can build up in the combustion chamber and affect performance. Using proper cleaning methods, such as fuel additives or manual cleaning, can help remove these deposits and restore smooth engine operation.

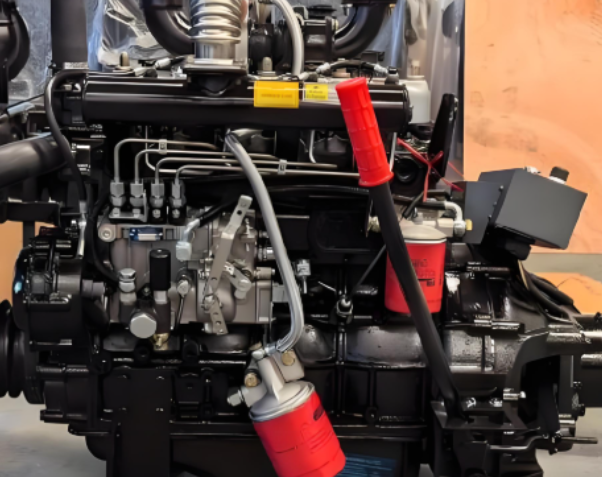

How to Improve Diesel Engine Reliability?

To extend the lifespan of your diesel engine and reduce the likelihood of failures, it’s crucial to follow a few key maintenance practices. These steps not only enhance engine performance but also ensure reliability in the long run.

Essential Maintenance Tips:

Regularly Change Engine Oil and Filters: Regular oil and filter changes are vital for keeping the engine’s moving parts lubricated and free from contaminants. This reduces wear and tear and ensures smoother engine operation.

Clean the Air Filter and Ensure Unobstructed Airflow: A clean air filter ensures proper airflow to the engine, which is crucial for efficient combustion. Regularly clean or replace the air filter to avoid restrictions that could negatively affect performance.

Check Battery Voltage and Wiring: A well-maintained battery is essential for reliable engine starts. Regularly inspect the battery’s voltage and ensure all connections are clean and tight. Faulty wiring or low battery voltage can cause starting issues.

Use High-Quality Diesel and Avoid Water Contamination: Always use high-quality fuel to ensure efficient combustion. Contaminants like water in the diesel fuel can lead to poor engine performance and even damage critical components. Properly store fuel and check for water contamination before use.

Regularly Maintain the Fuel Injection and Cooling Systems: Keep the fuel injection system in top condition by checking injectors and fuel lines for wear or clogging. Similarly, the cooling system should be maintained to ensure the engine stays at the right operating temperature to prevent overheating.

Bonus Tip: Equip with Cqstart Spring Starter to Enhance Emergency Starting Capabilities

In remote job sites, offshore platforms, or emergency power systems, where reliable electrical power may not always be available, it’s advisable to equip diesel engines with a mechanical spring starter as a primary or backup starting method.

Cqstart Spring Starter is a highly reliable and adaptable solution that has helped many users overcome the challenges of “battery failure and inability to start. By utilizing a high-strength spring mechanism, it ensures that the engine can be started without relying on electrical systems, making it a perfect choice for harsh environments and emergency situations.

Final Thoughts

Maintenance of diesel engines is all about prevention. Identifying common problems and addressing them promptly is key to ensuring the smooth operation of your equipment. For starting issues, Cqstart Spring Starter offers an efficient, safe, and battery-free solution, especially suitable for extreme conditions or environments without electrical power.

If you are looking for the right starting solution for your equipment or want to learn more about the different models and compatibility of Cqstart Spring Starters, feel free to contact Cqstart. We will provide you with professional technical support and selection advice.