6.7L Cummins diesel engine is renowned for its wonderful performance and exceptional reliability and therefore it is the cornerstone of heavy-duty Ram trucks, construction machinery, power generators, etc.

However, even the most powerful engines are going to face issues once subjected to prolonged and arduous use. In this article, we will discuss common 6.7 Cummins problems, preventive measures that work, and introduce a highly dependable emergency starting solution, spring starter, to help keep your engine going when you most need it.

Part 1. What is 6.7L Cummins Engine?

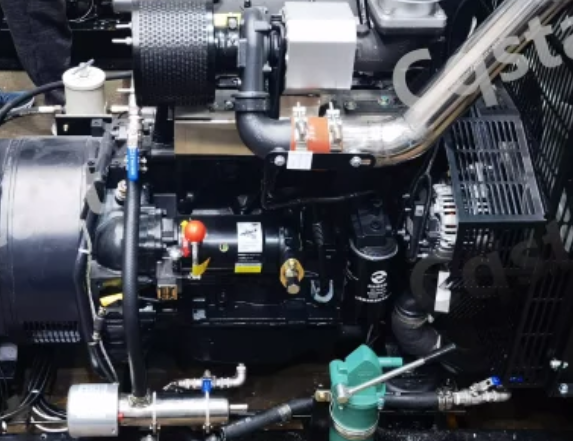

6.7L Cummins turbo diesel engine, initially produced in 2007, is now a standard powerplant in heavy-duty uses. This in-line six cylinder engine, constructed to withstand rising power demands, efficiency, and emissions controls, is typically used in Ram heavy-duty pickup trucks, heavy-duty construction machinery, farm machinery, and industrial genset generators.

One of the most striking features of the 6.7 Cummins is the huge amount of torque produced that equates to horsepower towing, hauling, and powering heavy machinery. It can produce up to 400 horsepower or over 1,000 lb-ft of torque and can be employed for either commercial or off-road use based on its configuration.

Besides brute force, the engine is also commended for its fuel efficiency, which minimizes cost of operation in the long term. Its heavy-duty nature is emphasized through a cast iron block, forged steel crankshaft, and high-pressure common-rail fuel system, which delivers enhanced ruggedness and long lifespan even in very hard operating conditions.

However, as with any high-performance mechanical configuration, there are also drawbacks for the 6.7L Cummins. Over a period of usage, there have been some issues encountered, especially by old engines or very used engines.

Familiarity with these issues is crucial in keeping maximum performance and avoiding untimely downtime. In the pages that follow, we will discuss the common issues in more detail, including practical solutions and preventive factors.

Part 2. 6.7L Cummins Engine Common Issues and How to Fix

While the 6.7L Cummins engine is celebrated for reliability, durability, and torque-rich performance, continued use, especially in heavy-duty or adverse environmental situations, may lead to an assortment of common mechanical and electronic issues. The following is a detailed discussion of widespread issues, symptoms, root causes, and real-world resolutions.

1. Turbocharger Failure

Symptoms:

- Noticeable loss of engine power

- Increased black smoke from the exhaust

- High-pitched whining or metallic grinding noises

Causes:

- Excessive soot and carbon buildup

- Inadequate lubrication or dirty engine oil

- Worn or damaged turbo components

Solutions:

- Clean the turbo regularly

- Replace oil and filters as per schedule

- Replace the turbocharger if necessary

2. EGR Valve Clogging (Exhaust Gas Recirculation)

Symptoms:

- Rough idling or engine stalling

- Reduced fuel efficiency

- Check engine light or high emissions

Causes:

- Carbon fouling in the EGR valve and passages

- Incomplete valve movement (stuck open or closed)

Solutions:

- Periodic EGR cleaning

- Replace the valve with OEM-quality parts when cleaning is no longer effective

3. DPF Blockage (Diesel Particulate Filter)

Symptoms:

- DPF warning light

- Loss of power or limp mode activation

- Higher-than-normal fuel consumption

Causes:

- Incomplete regeneration due to short trips

- Excessive soot accumulation

Solutions:

- Perform manual or forced regeneration

- Use fuel additives or DPF cleaners

- Replace DPF unit if severely clogged

4. Grid Heater Problems

Symptoms:

- Difficult cold starts

- Extended cranking time in winter

- Check engine light (often related to intake air heater circuit)

Causes:

- Failed grid heater relay or solenoid

- Faulty wiring or poor ground connections

- Heater element burnout due to wear or electrical issues

Solutions:

- Inspect and replace faulty relays or fuses

- Test grid heater operation during cold start cycles

- Replace the heater element if it’s no longer functioning

Note: A malfunctioning grid heater can greatly impact cold-weather starting reliability, especially in northern climates.

5. Fan Clutch Failure

Symptoms:

- Engine overheating under load

- Fan not engaging properly

- Loud fan noise or, conversely, fan not spinning at high speeds

Causes:

- Faulty fan clutch solenoid or temperature sensor

- Hydraulic or electronic control failure (depending on model)

- Contamination or mechanical wear in the fan clutch

Solutions:

- Diagnose fan clutch engagement with a scan tool

- Replace faulty solenoids or the entire fan clutch assembly

- Ensure proper coolant temperature sensor function

Tip: Cooling system issues are especially critical during towing or in hot climates—address fan clutch problems promptly to avoid engine damage.

6. Starting Issues or Electrical System Failures

Symptoms:

- Diesel engine not starting or slow crank

- Dead battery or frequent battery drain

- Failed starter motor

Solutions:

- Weak or aging batteries

- Faulty wiring or poor electrical connections

- Burnt starter motor

Recommendation:

For off-grid, cold-weather, or emergency use, consider a spring starter. It provides a mechanical, battery-free way to start the engine, making it highly reliable for backup or primary starting needs in remote environments.

Part 3. Why Consider Using a Spring Starter for 6.7L Cummins?

In many 6.7L Cummins applications, the traditional electric start system, battery, and starter motor, is common but not always reliable, especially in unstable power or harsh environments where failures can leave equipment stranded.

The spring starter, like Cqstart spring starter, offers a simple, reliable, and power-free alternative. By pre-tensioning a high-energy spring manually, it stores energy that will, upon release, rotate the engine crankshaft to drive the engine—no battery, wiring, or external power is needed, and it is not affected by temperature and humidity.

Ideal Applications for the 6.7L Cummins Engine with a Spring Starter:

Emergency Generator Sets

Generators may remain idle for extended periods of time, during which batteries can discharge or circuitry can fail.

A spring starter may serve as the primary or auxiliary starting system to deliver reliable start-up when power is most essential.

Construction Machinery (i.e., excavators, rollers, drilling rigs)

Construction sites typically have no stable power sources, and batteries are exposed to vibration and temperature extremes.

There is reduced dependency on electrical systems with a spring starter, enhancing the equipment’s self-starting ability in the field.

Marine and Port Equipment

Continuous exposure to damp, salty conditions causes electrical components to corrode and fail on a regular basis.

Mechanical spring starters are impervious to moisture issues and are ideally suited for ship engines, emergency pumps, cranes, and other marine applications.

Military Vehicles and Field Equipment

Missions require flawless startup systems that are low-maintenance, simple, and ultra-reliable.

Spring starters require no batteries and are immune to extreme cold, dust, and rough terrain, making them the perfect choice for military-spec power units.

Key Advantages of Spring Starters:

Fully Mechanical, No Electric Power Needed: Eliminates battery dependency and electrical wiring problems.

Simple, Robust Design: Consists mainly of springs, gears, and release mechanisms, with fewer parts to maintain and less chance of breakdown.

Highly Resistant to Environmental Extremes: Reliable performance in extreme cold (down to -40°C), high humidity, dusty, or high-altitude conditions.

Easy to Install and Highly Suitable: Fits 6.7L Cummins engine and a broad range of other diesel platforms such as Cummins 4BT, 6BT, and ISDe series, with custom fittings available.

Perfect as Primary or Emergency Backup Starting System: Perfect as part of a dual-start system (electric + spring) to improve redundancy and operating safety.

Part 4. How to Prevent Common Issues with the 6.7L Cummins Engine?

For the purpose of extending the service life of the 6.7L Cummins engine, ensure stable and optimal operation for a long period of time, minimize the likelihood of failure, and maintain personnel and owners, we recommend the following important maintenance precautions:

1. High-Quality Diesel Oil and Fuel Should Be Used

Using manufacturer-recommended diesel fuel and engine oil is of most significance in the delivery of adequate lubrication and healthy combustion inside the engine.

Low-quality fuel has water or contaminants, leading to clogged injectors and unhealthy combustion, and low-quality oil leads to wear and shortens the engine’s life. Use certified brands of oil and fuel and change them as frequently as manufacturer instructions.

2. Change Air and Fuel Filters Regularly

Air and fuel filters remove contaminants from the air and fuel intake, protecting engine components from contamination. Dirty or clogged filters reduce air intake and hinder fuel supply, resulting in power loss and poor fuel economy. Filters must be inspected routinely and replaced if driving in dusty conditions or where fuel purity is uncertain.

3. Clean the Intake System and EGR Parts on Time

The intake manifold and EGR parts are susceptible to carbon deposits and dirt that clog the airflow and cause emissions issues. Intake manifold, throttle body, and EGR valve cleaning on a periodic basis helps keep a free airflow, reduce emission issues, fuel economy, and improves engine performance.

4. Check Diesel Particulate Filter (DPF) Condition on a Regular Basis

The DPF is a critical emissions reduction system that traps particulate matter from exhaust. A fouled DPF will result in loss of power and poor fuel efficiency.

Having the DPF checked a minimum of once each year, regeneration or professional cleaning products as required, should be performed in order to verify that it is operating and not impeding the engine’s performance.

5. Install a Spring Starter on Remote or Critical Equipment

In the field, in hostile environments, or on critical equipment, the electrical start system may be lost due to battery drain or electrical malfunction. The installation of a spring starter as an auxiliary means of starting provides power-independent capability, with voltage-independent engine starting when most required, ensuring operation is significantly more reliable and safer.

Final Thoughts

6.7L Cummins engine delivers great performance but may be riddled with structural or environmental issues. Through routine maintenance, timely repairs, and the installation of quality auxiliary equipmentsuch as spring starters, you can successfully augment the stability and starting reliability of your equipment.

Are you searching for a quality spring starter to install in your diesel engine?

At Cqstart, we supply diesel engine spring starters from 1 to 50 liters. They can be used for industrial, marine, military, and other applications, with reliability, safety6.7L Cummins diesel engine is renowned for its wonderful performance and exceptional reliability and therefore it is the cornerstone of heavy-duty Ram trucks, construction machinery, power generators, etc.