Engineering vehicles, power generation equipment and remote machinery rely heavily on reliable starting of diesel engines to operate smoothly. Failure to start up in remote, cold or extreme environments could have serious repercussions for their projects; any delays, financial losses and safety risks could ensue as a result.

To combat these challenges, more users are turning to heavy-duty jump starters for diesel as a form of protection. Did you know that spring starters are also a more reliable and hassle-free solution for certain applications?

In this post, we will guide you through a deep dive into these two types of starting devices. Let’s explore them!

Part 1. What is Heavy-Duty Jump Starter for Diesel?

Heavy-duty jump starters for diesel engines are portable energy devices designed to deliver an instant surge of starting current when an engine fails to start due to weak or dead battery, particularly during cold weather conditions.

While standard passenger vehicle jump starters offer similar services, heavy-duty models offer increased peak current output, greater battery capacity, and enhanced cold weather performance compared to their counterparts.

These robust devices are essential tools in industries where downtime is both expensive and dangerous, providing a fast and cost-effective means of restoring engine operation without towing or on-site maintenance services.

Common Application Scenarios:

Commercial Trucks & Tractor-Trailers: Logistics and freight companies often enlist logistics providers like logistics to jump start long-haul diesel trucks, refrigerated trucks and other heavy commercial vehicles that have sat idle for extended periods or experienced battery drain due to onboard electronics.

Construction Machinery: Power reliability can often be an issue on job sites with limited infrastructure; excavators, bulldozers, wheel loaders and road rollers in particular require reliable power sources in order to operate effectively.

Agricultural Equipment: Ideal for starting large farm machines like harvesters, combine harvesters and tractors during early morning or cold weather periods when batteries may underperform.

Where engine failure could result in significant delays, such as mining sites, oil fields, forestry camps or remote infrastructure projects, using a heavy-duty jump starter can ensure quick recovery without waiting for external help to arrive.

Standby Diesel Generators:

Frequently used to jump-start diesel gensets that have been sitting unused for long periods, especially in facilities where backup power is critical but maintenance intervals are long.

Remote Area Emergency Starts:

In mining sites, oil fields, forestry camps, or remote infrastructure projects, where engine failure can lead to costly delays, a heavy-duty jump starter ensures quick recovery without waiting for external assistance.

Part 2. Pros & Cons of Heavy-Duty Jump Starter for Diesel

Heavy-duty jump starters are a convenient solution for quickly revitalising diesel engines, especially on the move. While these devices offer strong performance and portability, there may also be limitations in certain conditions that restrict them. Let’s discuss some of their main advantages and disadvantages below.

Pros:

Fast Emergency Start-Up & Easy to Carry

Heavy-duty jump starters are designed for immediate deployment in emergency situations, making them the ideal solution for mobile service teams or on-site operators who require immediate power to start diesel engines without waiting for backup support. Their portable design makes them great additions for service vehicles or on-site operators who require immediate power without waiting.

Modern Power Banks With Multi-Functional Utility

Many modern models function as multifunctional portable power banks, featuring USB ports, LED lights, and DC/AC output for charging laptops, tools, and other electronic devices, making them highly useful in field operations.

Supports 12V and 24V Systems

These units are specifically designed to be compatible with both 12-volt and 24-volt electrical systems, making them suitable for a range of diesel machinery ranging from light commercial vehicles to off-road equipment.

Cons:

Battery Dependency

Since these units rely on internal lithium or AGM batteries, regular charging and maintenance are essential. Over time, battery degradation can reduce both peak current output and overall performance, especially if not stored or maintained properly.

Not Suitable for Hazardous or Explosive Environments

Heavy-duty jump starters often contain electrical circuits and lithium batteries, which pose ignition risks. This makes them unsuitable for use in hazardous environments such as oil and gas platforms, chemical plants, or confined engine rooms on ships where explosion-proof standards are mandatory.

Reduced Performance in Low Temperatures

Lithium-ion batteries are sensitive to cold; in extreme winter conditions, their ability to deliver high current may drop significantly. This can render the jump starter unreliable when it’s needed most—during early morning starts or in polar environments.

Requires Electrical Operation

Operating a heavy-duty jump starter involves connecting clamps, setting voltages, and ensuring safe contact with battery terminals. These tasks require a stable and safe electrical environment, making them less suitable for locations with unpredictable or unstable electrical conditions.

Part 3. What is Spring Starter?

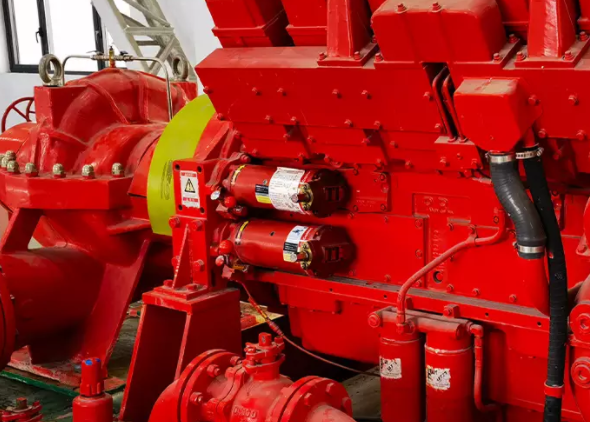

A spring starter is a completely power-free starting device designed specifically for diesel engines. Unlike electrical starters, it operates purely through mechanical energy. The process involves manually winding a powerful internal spring, which stores potential energy. When released, this energy rapidly turns the diesel engine’s crankshaft, initiating the combustion process and starting the engine.

The key advantage of a spring starter lies in its purely mechanical design, zero electrical power requirement, and minimal maintenance needs.” This makes it an ideal solution for applications where battery power is unavailable, unreliable, or hazardous. Its simplicity and robustness enable reliable engine starts even after long periods of inactivity or in extreme environments.

Common Application Scenarios:

Marine Lifeboat Engines:

Spring starters are widely used in lifeboat engines to guarantee reliable starting in emergency evacuation scenarios where electrical power may be inaccessible or unsafe.

Underground and Explosion-Proof Equipment:

These starters is kind of a explosion-proof diesel engine starter that comply with strict safety certifications such as ATEX, making them suitable for use in hazardous environments like mines and other underground installations where spark-free, explosion-proof equipment is mandatory.

Remote Diesel Generator Sets:

In off-grid or isolated locations, mechanical spring starters provide a fail-safe way to start generators without relying on batteries or external power sources.

Oil Platforms and Chemical Plants:

In highly flammable or explosive environments, spring starters are preferred due to their zero electrical ignition risk, ensuring safe and reliable engine starts.

Emergency Equipment Requiring Long-Term Reliability:

For equipment that may remain unused for extended periods, yet must start reliably when needed, mechanical spring starters offer unmatched dependability without the concerns of battery degradation or electrical failure.

Part 4. Comparison: Heavy-Duty Jump Starter vs Spring Starter

Selecting an optimal starting solutions for your diesel engine depend heavily on its operational needs and environment. Both heavy-duty jump starters and mechanical spring starters have distinct advantages and drawbacks that may make one superior over another in certain circumstances. Here we make a table compares their key features across several important criteria.

| Features | Heavy-Duty Jump Starter | Mechanical Spring Starter |

| Power Source Required | ✅ Requires charging | ❌ No power needed |

| Maintenance Frequency | Moderate, requires regular charging and battery checks | Very low, occasional spring winding only |

| Reusability | Depends on battery charge | Manually reusable each time |

| Explosion-Proof Support | ❌ Not suitable | ✅ Supported, some models with ATEX certification |

| Ease of Operation | One-button start | Requires initial familiarization with the operation |

| Service Life | Limited by battery lifespan | Mechanical structure with long service life and high reliability |

| Suitable Environments | General emergency situations | Extreme, critical, hazardous, or power-free environments |

Part 5. Why is It Recommended to Use Both Together?

In most applications, heavy-duty jump starters prove to be highly practical, especially for vehicles and power equipment that require frequent daily starts. Their portability and quick response make them the preferred choice for routine operations.

However, there are specific scenarios where relying solely on a jump starter may not be sufficient or safe, and this is where mechanical spring starters come into play.

Consider opting for a spring starter when:

Battery Power Cannot Be Reliably Maintained or Kept Fully Charged

In remote locations or during long equipment downtime, batteries can lose charge or degrade, making jump starters less dependable.

Equipment Is Located in Explosion-Proof Zones Where Electrical Starters Are Prohibited

Environments such as oil rigs, chemical plants, or mines require spark-free solutions that only mechanical starters can safely provide.

Operating in Extremely Cold or Harsh Climates Where Battery Performance Is Severely Limited

Lithium-ion and other battery types suffer significant efficiency loss in low temperatures, compromising jump starter effectiveness.

Emergency or Lifesaving Equipment That Demands 100% Reliable Starting

In critical situations, any failure to start can have catastrophic consequences, making a purely mechanical, maintenance-free backup essential.

By pairing a mechanical spring starter with a heavy-duty jump starter, you create a redundant starting system that covers the weaknesses of each. For diesel engines that are used infrequently, kept in harsh environments, or considered mission-critical, having a spring starter on hand is akin to purchasing “startup insurance”—ensuring your engine will turn over reliably when it matters most.

Conclusion: Choosing the Right Starting Solution for You

No matter who you are – from truck drivers and equipment managers in construction sites, to managers responsible for diesel engine operations in marine or chemical environments – asking “how to start” directly impacts equipment reliability and longevity.

Heavy-duty jump starters are perfect for daily use and flexible mobility, while mechanical spring starters may be better suited to low-frequency but critical tasks. By selecting or even combining these two types of starters based on your equipment type, environmental conditions, and maintenance capabilities, you can significantly enhance the safety and continuity of your operations.

Looking for a reliable mechanical spring starter? Cqstart offer professional solutions to support various diesel engine models. Contact us for more detailed information.