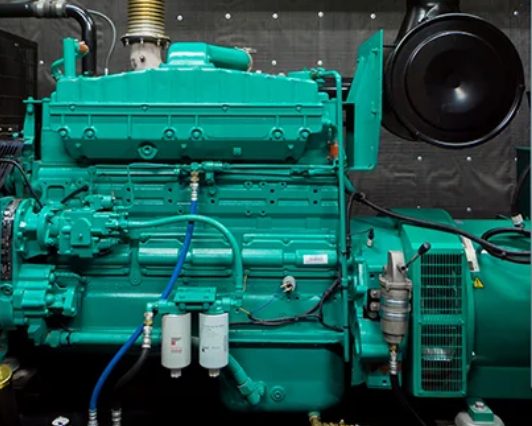

In critical moments such as power outages, natural disasters, or sudden failures of electronic control systems, knowing how to manually start a diesel generator can be a life-saving skill. While most modern diesel generators are equipped with electric or automatic start systems, they become useless when the battery is drained, the wiring fails, or the controller crashes.

In such situations, manual starting becomes the only option, like holding the key to reignite hope in the dark. Here, we will guide you through on how to start diesel generator manually, helping you stay calm and take control when it matters most.

Part 1. When Do You Need to Manually Start a Diesel Generator?

Under normal conditions, diesel generators can be quickly and easily started using an electric start system. However, there are several situations where manual starting becomes necessary, and being prepared for these scenarios can make a critical difference:

Battery is Drained or Aged

Over time, generator batteries can lose their capacity or become fully discharged, especially if the equipment hasn’t been maintained regularly. In such cases, the electric start system fails, and manual starting is the only viable option.

Starter Relay or Controller Malfunction

A faulty relay or an unresponsive control module can interrupt in the electric starting sequence. This type of electrical failure often happens without warning, leaving operators with no choice but to resort to manual methods.

Automatic Start System Failure

While automatic start systems are designed for convenience and remote operation, they are not immune to software bugs, wiring issues, or sensor errors. When the auto-start fails, manual intervention is required to get the generator running.

Emergency Drills or Remote Environments

In emergency preparedness drills, or in areas where there is no access to external power—such as outdoor operations, remote construction sites, or rural installations—manual starting ensures the generator can operate independently and reliably.

Generators Equipped with Non-Electric Start Systems (e.g., Spring Starters)

Some generator models, especially those designed for rugged or off-grid use, come with mechanical starting mechanisms like spring starters. These systems are intentionally designed to function without any electrical power, making them ideal for harsh environments.

Part 2. Safety Checks and Preparations Before Manual Starting

Before manually starting a diesel generator, it is essential to carry out the following safety checks and preparatory steps:

Wear Personal Protective Equipment (PPE):

Use appropriate PPE such as gloves, safety goggles, and earplugs to protect yourself from potential hazards like high temperatures, moving parts, or excessive noise.

Check Fuel Level:

Ensure that the fuel tank has sufficient diesel and that the fuel is clean—free from water or contaminants that could affect engine performance.

Inspect Engine Oil and Coolant Levels:

Low oil levels can lead to dry friction and serious engine damage, while inadequate coolant can cause the engine to overheat during operation.

Disconnect All Loads:

Make sure the generator is not connected to any electrical loads before starting. Starting under no-load conditions allows the engine to accelerate smoothly and stabilize more easily.

Examine the Air Filter:

A clogged or dirty air filter can restrict airflow, making the engine harder to start and reducing overall efficiency.

Part 3. How to Manually Starting a Diesel Generator?

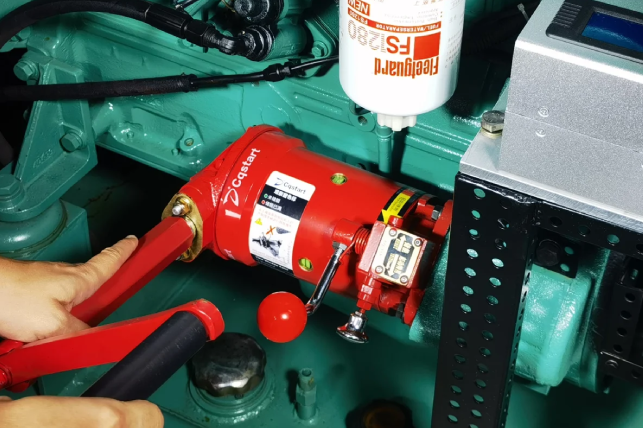

Here’s a detailed, step-by-step guide for manually starting a diesel generator, applicable to models equipped with hand crank starters, pull-start mechanisms, or spring starters (such as the Cqstart spring starter):

1. Open the Fuel Valve:

Ensure the fuel supply is open and flowing properly. This is crucial to avoid any fuel starvation during startup, which could lead to failure to start the engine.

2. Set the Throttle and Preheat (If Applicable):

Some generator models require manual adjustment of the throttle or activation of a preheat button to prepare the engine for a smooth start. Ensure the throttle is set to the correct position for starting, and if the model has a preheating feature (like glow plugs), make sure to engage it for optimal performance.

3. Insert the Starting Mechanism:

For Spring Starter: Confirm that the spring has been properly wound and is ready for release. This ensures the mechanical energy is stored and ready to initiate the engine’s rotation when released.

For Hand Crank or Pull-Start Mechanism: Check that the starting mechanism is free from obstruction and operates smoothly. This will ensure that the crank or cord can turn the engine effectively.

4. Initiate the Starting Process:

Spring Starter: Once you’ve wound the spring starter, release it carefully. The spring will provide the necessary force to turn the engine over and ignite the fuel.

Pull-Start Mechanism: With a firm grip, quickly and forcefully pull the starting cord. This action should spin the engine and initiate the combustion process.

Hand Crank Starter: Begin steadily turning the hand crank. Keep a consistent speed, and be patient; the engine should eventually turn over and start.

5. Observe the Engine’s Running Condition:

After successful startup, closely monitor the generator’s operation. Pay attention to:

Unusual Noises: Listen for any knocking, rattling, or irregular sounds that may indicate mechanical issues.

Excessive Smoke: A slight puff of smoke is normal during startup, but if the exhaust smoke remains thick and black or blue, it could signal a problem with the fuel system or engine.

6. Gradually Connect the Load:

Once the generator is running smoothly and there are no visible or audible issues, you can start connecting the required electrical loads. Begin with smaller equipment and gradually add more to avoid overloading the generator.

Pro Tip: If you are using a spring starter, such as the Cqstart, you don’t need a battery for the startup, making it especially useful in remote areas, construction sites, or harsh environments with high humidity or extreme cold. This system allows you to start the generator easily, regardless of electrical power availability.

Part 4. What to Do If Manual Starting Fails?

Even if you have followed every step correctly, manual starting may occasionally fail due to mechanical or fuel-related problems. Below is a detailed guide to common faults, their possible causes, and suggested solutions to help you get your diesel generator running again:

| Issue | Possible Causes | Recommended Solutions |

| Generator Fails to Ignite | – Fuel line blockage due to dirt or trapped air- Empty fuel tank or fuel contaminated with water or debris– Clogged air filter causing poor air intake | – Inspect the fuel lines for blockages or air bubbles and remove them- Refill the fuel tank with clean diesel, ensuring it’s free of water or sediment- Clean or replace the air filter to ensure proper airflow |

| Starter Cord or Crank Won’t Move | – Engine seized or stuck due to lack of lubrication or mechanical failure- Pull cord mechanism jammed or broken | – Check for obstructions or damage around the flywheel- Lubricate and clean the crank or starter mechanism- If internal components are jammed, consult a technician |

| Engine Starts Then Stalls Immediately | – Throttle set incorrectly, resulting in insufficient fuel during run mode- Contaminated or poor-quality fuel impeding consistent combustion | – Adjust the throttle to the correct starting and running position- Drain and replace the old fuel with clean, filtered diesel- Check for water or sludge in the fuel sediment bowl |

| Unusual or Loud Starting Noise | – Loose or misaligned internal components, such as valves, bolts, or mounting brackets- Starter mechanism improperly installed or damaged | – Stop the startup attempt immediately to avoid further damage- Conduct a full inspection of the engine housing and mounting parts- Tighten any loose components, realign the starter, and check for signs of wear |

Part 5. More Tips for Starting Diesel Generator Smoothly:

Routine Maintenance is Key:

Regularly inspect and service the fuel system, filters, starter mechanism, and lubrication system. Preventive maintenance greatly reduces the chance of starting failures.

Use Clean Fuel and Store Properly:

Always use clean, high-quality diesel and store it in sealed containers to avoid moisture contamination, especially in humid or outdoor environments.

Test the Manual Start System Periodically:

Even if you primarily rely on electric or automatic starting, test the manual start method regularly to ensure it functions smoothly when truly needed.

Spring Starter Users:

If you use a spring starter, ensure the winding mechanism is well-maintained and free of dirt or corrosion. If the spring tension feels weak or doesn’t engage properly, servicing or replacement may be necessary.

By understanding these common issues and how to address them, you’ll be better prepared to troubleshoot your diesel generator in an emergency, helping to ensure reliable backup power whenever you need it.

Final Words

Whether facing a temporary power outage or operating in remote or extreme environments, mastering the manual starting technique for diesel generators is essential for ensuring stable electricity supply. Especially in situations without a battery or in cold, humid conditions, using a spring starter or other non-electric starting solutions can significantly improve starting efficiency and reliability.

Looking for a stable and reliable manual starting solution?

Cqstart offers professional-grade diesel engine spring starters, designed for battery-free operation, simple handling, and long-term durability. Feel free to contact Cqstart for more product details!