If you turn the key or pull the start lever, and the engine won’t start, it’s easy for you to become panicked. The sluggishness or that tinny clicking sound, feels like your engine is sending an alert. Whether you’re operating a generator, marine engine, construction machinery, or any heavy-duty diesel engine, a no-crank situation instantly raises one question: Is the heavy duty starter dead?

Before jumping into the worst-case scenario, it’s important to understand what really happens when a heavy-duty engine won’t crank — and why the starter, although often suspected first, is not always the culprit.

In this article, we walk you through what heavy-duty starters do, why failures happen, how to diagnose the issue, and how to choose a reliable replacement if needed — including spring starters like those from Cqstart that operate without batteries.

Part 1. How Heavy-Duty Starters Work?

Heavy-duty engines rely on starters with enough torque to rotate large diesel engines under compression. Traditionally, this has included electric starters powered by batteries. But in many industrial, marine, and remote applications, a different type of system is preferred: the mechanical spring starter.

Electric Starters vs. Spring Starters

Electric heavy-duty starters use a powerful battery to drive a high-torque electric motor.

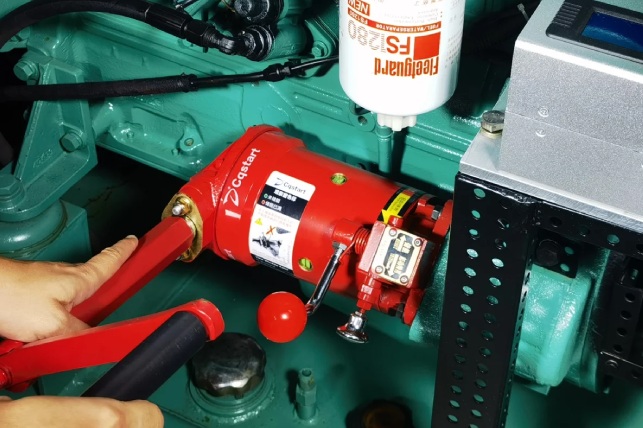

Spring starters, on the other hand, store energy mechanically. The operator winds the spring pack manually, and the stored energy is released in one burst to crank the engine.

This means spring starters can operate without any battery, wiring, or external power source, making them ideal for:

- Cold environments

- Marine or offshore conditions

- Backup/emergency engines

- Mining, agriculture, and remote field operations

A spring starter delivers torque through gear engagement and turns the engine’s flywheel just like an electric system — but with fewer failure points.

Part 2. Common Reasons That Could Cause Your Engine Not To Crank

Although a no-crank condition seems grave, it does not always mean that the starter has failed. The following are the most common reasons.

1. Weak / Dead Batteries (Electric Starter Motors)

In the event your system has electric starter motors, weakness or dead batteries are, most of the time, the first suspect. Batteries that are dead or weak are not able to supply enough current, resulting in slow cranking, popping sounds, or no sounds at all.

2. Internal Starter Failure

Heavy-duty starters do wear out over time. Common internal failures include:

- Worn or stripped gears

- A broken spring mechanism (for spring starters)

- Reduced torque output

- Clutch/pinion engagement failure

If the starter tries to spin the flywheel but slips or lacks force, internal damage may be the cause.

3. Jammed Engine or Excessive Mechanical Resistance

Sometimes the starter isn’t the problem — the engine is. Issues such as:

- Hydrolock

- Overheating

- Debris inside moving components

- Internal seizure

can prevent the engine from turning. Even the strongest starter cannot crank a seized engine.

4. Faulty Wiring or Loose Connections (Electric Systems)

Corroded terminals, damaged wiring, or loose connections can disrupt the power supply, mimicking a failed starter.

5. Improper Use of a Spring Starter

Because spring starters rely on hand-winding:

- Incorrect winding technique

- Insufficient stored spring energy

- Failure to engage properly

may result in no crank, even if the starter itself is perfectly functionaly amid vibrations and dust. Their low-maintenance feature reduces outdoor operational hassle and boosts work efficiency.

Part 3. How to Diagnose Whether Your Starter Is Actually Dead?

Before replacing anything, use this simple diagnostic process.

1. Perform a Quick Visual Inspection

Look for:

- Cracked or dented housing

- Rust or oil contamination

- Broken levers or gear teeth

These physical signs often reveal mechanical damage.

2. Try a Manual Rotation/Winding Test (for Spring Starters)

While winding the spring:

- Does it rotate smoothly?

- Does the spring store energy?

- Do you feel consistent resistance?

If winding is rough, impossible, or produces grinding, internal components may be damaged.

3. Listen for Abnormal Sounds

Different sounds indicate different issues:

- Clicking-electric starter receiving insufficient power

- Grinding – gear engagement failure

- Silence- electrical fault or complete starter failure

Identifying the sound gives you clues before you open anything.

4. Rule Out External Issues

Before assuming the starter is dead:

- Check battery voltage and terminals

- Inspect wiring (if electric)

- Ensure the engine isn’t locked or overheated

Many “starter problems” turn out to be external factors.

5. Evaluate Torque Output

If the starter spins but lacks torque:

- The internal mechanism may be worn

- The spring pack may have lost its strength

- The clutch might slip under load

Reduced torque is a strong indicator that replacement or major servicing is needed.

Part 4. Why Spring Starters Are Still the Best Choice for Many Heavy-Duty Engines?

Despite the prevalence of electric starters, spring starters remain a top solution for industrial and emergency applications – and here’s why.

1. Battery-Free Operation

No battery means:

- No electrical failures

- No charging needed

- No dependency on weather

This is crucial in marine, mining, and emergency systems where reliability is everything.

2. Extremely Durable Mechanical Structure

Spring starters are built with:

- Robust gears

- Hardened shafts

- High-strength spring packs

They withstand years of heavy use with minimal maintenance.

3. Reliable in Harsh Environments

Spring starters thrive where electric starters struggle – especially in:

- Freezing temperatures

- Moisture-heavy environments

- High vibration zones

- Corrosive offshore conditions

4. Long-Term Low Maintenance Cost

Spring starters have no batteries and fewer electronic components, yielding high reliability and long-term cost savings.

When Should You Replace the Starter?

Even with the right look after, heavy-duty starters come to the end of their service life. Consider replacing your starter if:

- It fails repeatedly after you troubleshoot,

- if the main gears and springs are broken, and the case cannot be repaired.

- It cannot generate sufficient torque

- You operate in mission-critical environments like marine rescue, industrial plants, or power backup systems

In these cases, a reliable new starter becomes essential.

Choosing a Reliable Heavy-Duty Spring Starter

When it’s time to replace your starter, choose carefully. Here’s what to look for:

- Torque rating-must match your engine’s displacement

- Gear ratio-ensures proper engagement

- Durability-corrosion resistance, seal quality, metal hardness

- Compatibility-with your specific diesel engine model

- After-sales support -crucial for industrial operators

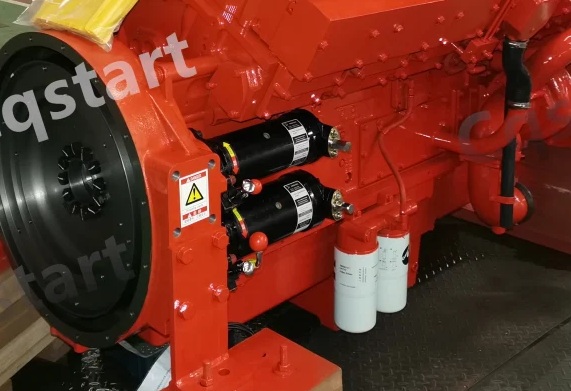

For those needing a dependable battery-free starter, Cqstart spring starters are a trusted option known for:

- High-output torque

- Strong spring packs

- Rugged marine-grade construction

- Reliable performance in extreme environments

Conclusion

No-crank heavy-duty starters don’t automatically mean your starter is dead. Many times, the fault lies within the battery, wiring, or the engine itself. A thorough diagnostic step beginning with the battery and working your way forward systematically should allow you to determine the real problem and avoid costly replacement and downtime.

And if it is the starter that is an issue at hand, high-quality spring starters to you offer glass-free high reliability for many years, especially in critical heavy-duty applications.