As the core of a ship’s power system, reliable starting of large marine diesel engines directly affects navigation safety, operational efficiency and costs. For an ocean-going cargo ship’s departure, a port tugboat’s scheduling, or a special ship’s emergency response, the engine’s stable starting under various conditions is the first defense for normal operation.

With larger ship tonnage, more complex power systems and diverse navigation challenges, providing stable, efficient starting assistance for these engines has become a key optimization issue in marine engineering. Next, we will analyze reliable starting solutions and propose optimization strategies based on starting’s key role and marine scenario challenges, offering technical references for practitioners.

Part 1. The Critical Role of Starting Large Marine Diesel Engines

The starting of a large marine diesel engine is no simple “ignition and operation” but a complex process involving power transmission, system coordination and safety control. Its reliable starting is critical throughout the ship’s operational cycle, manifested in three core dimensions.

1. Ensuring Navigation Safety

Ships face diverse emergencies at sea—emergency restart after main engine failure, power adjustment in rough seas, and precise control in narrow waterways—all demanding immediate engine starting. A failed start may cause power loss, leading to grounding or collisions. In tight port waters, frequent main engine starts/stops adjust course; delays or failures risk scratches with nearby vessels or docks. During ocean voyages, storms require rapid engine response to adjust speed and avoid risks, making start reliability key to emergency handling.

2. Boosting Operational Efficiency

The time taken to dock a cargo ship can have a significant impact on the transport cycle and profit. Slow starts and repeated failures increase loading/unloading times, as well as demurrage charges. An annual loss of 10-15 voyages can be caused by a 100,000-ton carrier that delays its start time per berth for an hour. Frequent starts and stops are important for fishing boats (trawling), engineering ships (offshore building), and other vessels.

3. Cutting Maintenance Costs

A start abnormality (insufficient torque or prolonged cranking), accelerates component wear and reduces lifespan.For example, subpar crankshaft speed causes poor fuel atomization, leading to cylinder carbon deposition, piston ring wear, and more overhauls. Maritime data shows start-related maintenance incurs high per-time costs and 1-2-week downtimes, disrupting operations. Conversely, reliable starting reduces mechanical impact, slows wear, extends maintenance intervals, and cuts long-term costs .

Part 2. Marine-Specific Challenges in Starting Large Marine Diesel Engines

Large marine diesel engines face more complex, harsher starting challenges than land-based ones, from equipment traits and ship environments, in four categories.

1. Impact of Extreme Environmental Conditions

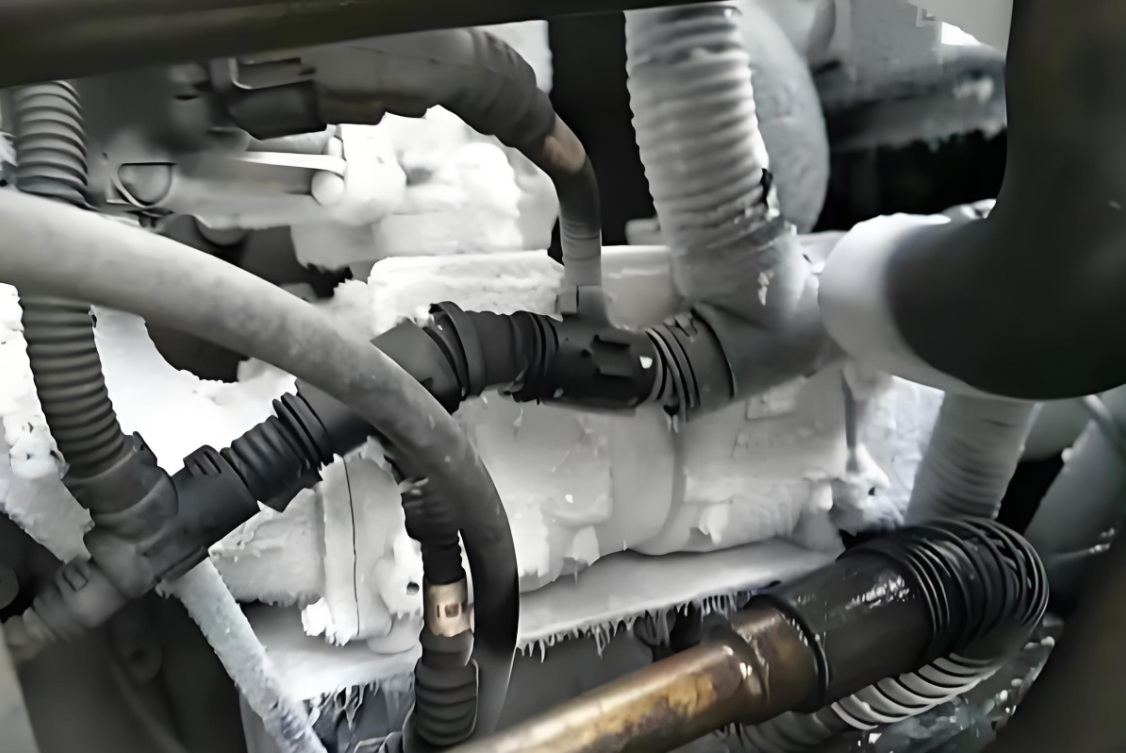

Ships sail globally and endure harsh environments–high/low temperatures, high humidity, and high salt fog–all disrupting the starting system. Low-temperature zones (e.g. Arctic routes, high latitude winter seas) are characterized by temperatures below -20degC. This thickens lubricating oils (which reduce fluidity and increase crankshaft resistance), deteriorates fuel atomization and causes combustion chambers to fail to reach ignition temperature, which lowers start success. High humidity and temperature in tropical seas accelerate the aging of electronic components (e.g. starter motor insulation failures, battery capacity losses), increasing faults. Salt fog can also cause metal parts to corrode (cylinder start valves and air pipeline joints), causing sealing problems and power transmission issues.

2. Limitations of Engine’s Own Characteristics

Large marine diesel engines have large displacement, high compression ratios, and heavy weight, needing far more torque/energy to start than land-based ones. A typical 12-cylinder model (over 100L displacement) drives tons of moving parts (crankshaft, piston) with over 1000N・m torque. Most use supercharging systems; cold starts bring insufficient supercharger pressure, leading to low cylinder air intake and added difficulty. Additionally, “one main engine, one propeller” setups force engines to overcome underwater propeller resistance. Anchored ships with partially submerged propellers see 30%-50% higher starting resistance, demanding more from the system.

3. Fluctuations in Ship’s Power Supply System

Ships rely on generators, whose voltage/frequency fluctuate with operating conditions (main engine load changes, auxiliary engine start-stops, equipment switching). Electrical components (starter motor, battery, control module) need stable power. Voltage below 80% of rated value cuts the starter’s output, lacking enough torque. Excessive fluctuations disrupt the control module, preventing accurate commands. In emergencies (e.g., main generator failure), emergency generators/batteries (limited capacity) take over; high starting system energy consumption may overload them, expanding faults.

4. Starting Difficulties After Long-Term Shutdown

Ship engines may shut down for over a month (maintenance, berthing). During this period, lubricating oil flows back to the oil pan (leaving cylinder walls/piston rings rusted), fuel in pipelines precipitates (blocking injectors/filters), and moving parts (starter gears, cylinder start valve spools) get stuck. These issues increase resistance, disrupt fuel supply, and lower first-start success. Statistics show such failures account for over 40% of annual start faults, a common maritime maintenance issue.

Part 3. Cqstart Spring Starter–Optimal Choice for Large Marine Diesel Engines

Faced with multiple challenges in marine scenarios, traditional starting solutions such as compressed air starting and electric starting can hardly fully meet the reliable starting needs of large marine diesel engines. However, the Cqstart spring starter, with its unique structural design and performance advantages, has gradually become the preferred solution in this field.

Why Choose the Cqstart Spring Starter?

Compared with traditional starting solutions, the Cqstart spring starter demonstrates significant advantages in addressing marine challenges, perfectly matching the starting requirements of large marine diesel engines:

Strong Environmental Adaptability

It does not rely on electrical components or compressed air systems and is not affected by high/low temperatures, high salt fog, or high humidity. Within the temperature range of -40°C to 60°C, the spring maintains stable performance and can normally complete energy storage and release. Its metal parts are treated with anti-corrosion coatings to resist salt fog erosion, with a service life of over 10 years—far exceeding the average 5-year service life of traditional starting systems.

Stable Starting Power

The main spring is made of high-strength alloy material, featuring large energy storage capacity and the ability to provide continuous and stable starting torque, unaffected by power supply fluctuations or air pressure changes. Even if parts get stuck after the engine is shut down for a long time, the torque released by the spring can still overcome additional resistance, achieving a starting success rate of over 95%—much higher than the 70% of electric starting and 80% of compressed air starting.

High Independence and Strong Emergency Capability

It does not depend on the ship’s power supply system or compressed air system and can be used as an independent starting solution. In extreme cases such as main power supply failure and emergency generator non-startup, the engine can be started only by manual energy storage, providing key power support for the ship’s emergency response. Additionally, it has a simple structure with no complex pipelines or electrical circuits, resulting in fewer fault points and maintenance costs only 50% of those of traditional starting systems.

Adaptability to High-Resistance Starting Scenarios

To address the large displacement, high compression ratio of marine diesel engines and the underwater resistance of propellers, the Cqstart spring starter can provide starting solutions with different torques (maximum torque up to 2000N・m) by adjusting spring specifications. Cqstart spring starters are compatible with various large marine diesel engines, meeting the starting needs of ships of different tonnages, and can support diesel engines with a maximum displacement of 50 liters.

Part 4. Strategies to Optimize Starting Performance of Large Marine Diesel Engines

Beyond choosing a reliable starting solution, systematic optimization is needed to enhance large marine diesel engines’ starting performance and reliability across conditions. These strategies cover maintenance, environmental adaptation, and system coordination, complementing the starting solution for comprehensive support.

1. Strengthen Routine Maintenance

- Component Checks: Weekly inspect Cqstart spring starter’s energy storage and gear engagement; monthly lubricate connecting parts (gear shafts, bearings); quarterly disassemble to replace aged seals/worn gears.

- Engine Condition: Monthly check lubricating oil (replace by temperature); quarterly clean fuel filters/injectors. Before long shutdowns, add anti-rust oil to cylinders; for shutdowns over 1 month, manually turn the crankshaft weekly.

- Parameter Monitoring: Record starting time, speed, torque via the ship’s system. Address issues if time rises >20% or speed fluctuates >10%.

2. Environment-Adapted Measures

- Low Temperatures: Below -10°C, preheat cylinders to 50-80°C, heat fuel pipelines, and add low-temperature flow improvers to fuel.

- High Temp/Humidity: In tropical seas, cool electrical components (≤60°C), apply waterproof sealant to interfaces; spray anti-salt-fog coating on spring starter metals semi-annually.

- High Salt Fog: Rinse external parts with fresh water after berthing; monthly purge internal passages.

3. Optimize Power/Energy Coordination

- Stabilize Power: Use PMS to monitor voltage/frequency; cut non-essential devices if voltage <90% rated. Maintain batteries, replace those with >20% capacity loss quarterly.

- Compressed Air (if used): Keep pressure at 2.5-3.0MPa; heat pipelines in low temps, drain impurities regularly.

- Linked Control: Prioritize Cqstart normally; switch to electric/compressed air in emergencies. Auto-analyze failures (e.g., replenish spring energy, switch to emergency power).

In Conclude

The reliable starting of large marine diesel engines is the fundamental guarantee for a ship’s safe navigation and efficient operation, as well as a key link in coping with complex maritime environments. If your large marine diesel engine needs a more stable starting solution, it is recommended to choose the Cqstart spring starter and combine it with scientific maintenance methods to ensure the long-term reliable operation of the equipment.