In industrial production, emergency power, and construction machinery, diesel engines are vital for strong power and stability. Yet many fall into years of “dormancy” due to equipment upgrades, project pauses, or seasonal idleness. Direct restart attempts often fail or damage parts, as long idleness harms fuel, electrical, and mechanical systems—blind starts may speed up aging or cause accidents. This article covers idleness impacts, startup steps, spring starter benefits, and FAQs to help scientifically “awaken” dormant diesel engines.

Part 1. Impact of Long-Term Idleness on Diesel Engines

Long-term idleness is not “rest” for diesel engines; instead, it causes faults due to lack of operational protection, focusing on three core systems—fuel, electrical, and mechanical—all hindering startup.

(1) Fuel System Problems

Diesel’s chemical and physical properties change during long storage. Light components swell (reducing performance of combustion) and unsaturated hydrocarbons transform into gums and asphaltenes. The substances stick to tanks, lines and injectors, obstructing them from atomizing fuel. The inflow of moisture and air into idle tanks reduces the quality of the fuel and causes rusting to components and weakens supply stability. In combination, they cause inadequate fuel and inadequate atomization, which can lead to a failure in startup.

(2) Battery and Electrical Failures

Batteries made of lead self-discharge (1%-2% per day) eventually draining completely over time and developing sulfation layers which deteriorate capacity. Connectors and wires oxidize due to moisture or dust (causing an insufficient contact) as well as older wires with damaged insulation could cause short circuits, which can disable starters or burn components.

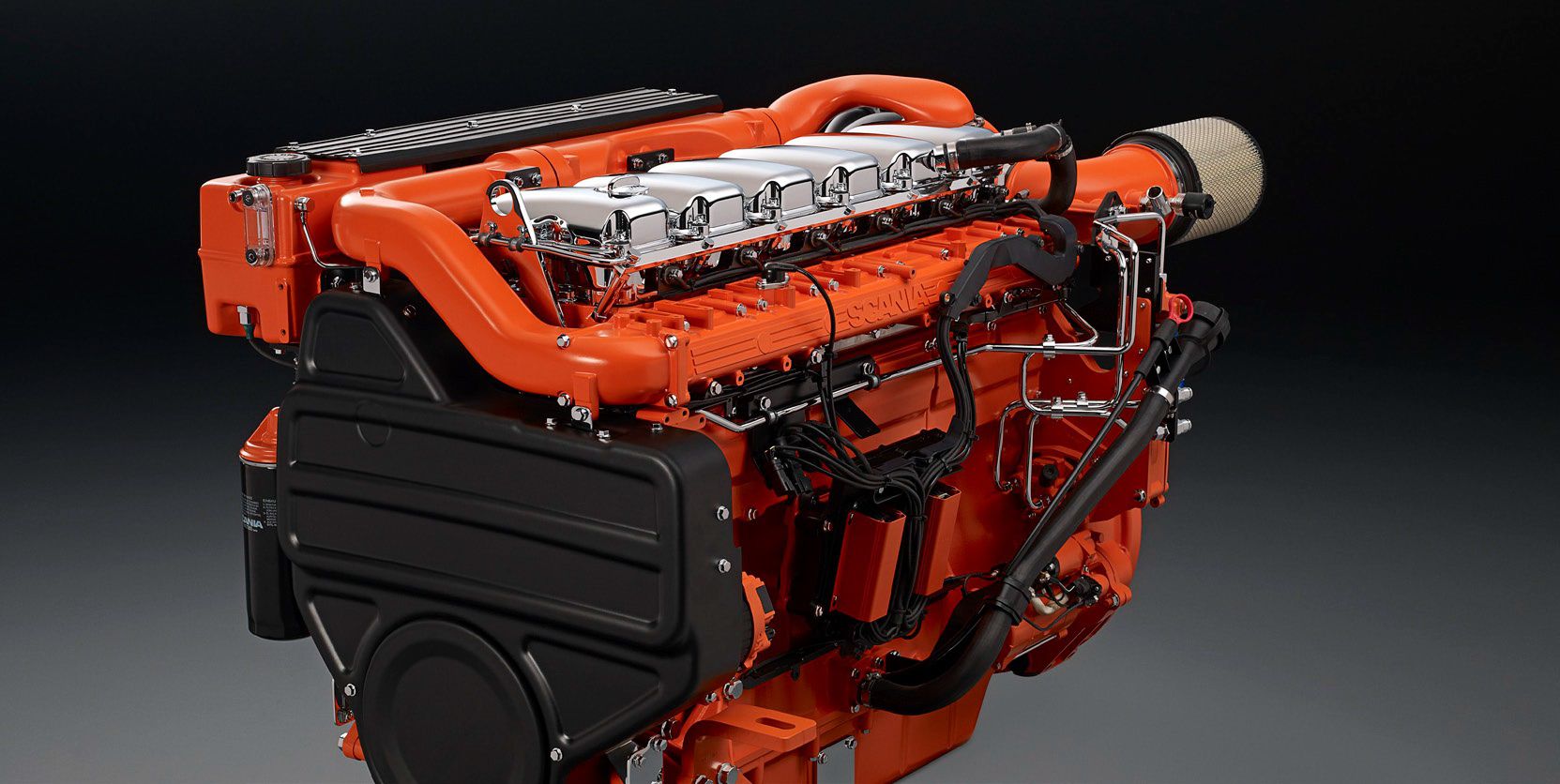

(3) Mechanical Rust & Seizure

Oil settles to the pan when idle, leaving parts unprotected. Air moisture rusts cylinder walls/pistons (increasing friction or causing “cylinder seizure”). Valves/valve seats leak due to carbon buildup/deformation (lowering compression pressure). Bearings/gears wear more from poor lubrication/dust, reducing precision and raising startup difficulty.

Part 2. How to Start Diesel Engine That’s Been Sitting For Years

Starting a long-idle diesel engine requires following the “inspection-maintenance-startup” process. Address potential faults first to minimize damage with scientific operations.

(1) Pre-Startup Inspection & Preparation

This fundamental step covers electrical, fuel, as well as mechanical systems.

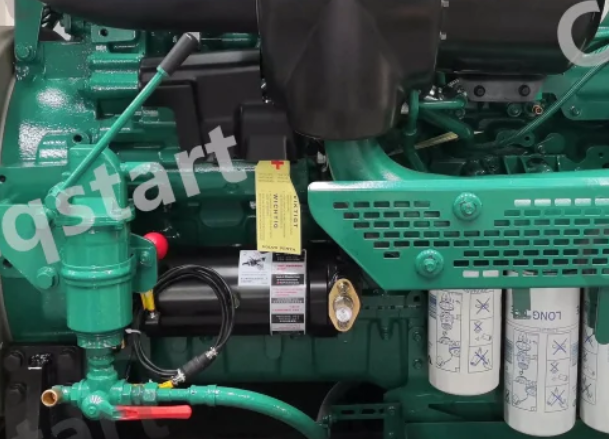

1. Fuel System Check

Take a small amount of diesel to examine the quality. Discard and flush the tank in case the fuel is stinky, dark, or turbid or has a lot of sediment. Cleaning the fuel tank (use detergent to remove heavy deposits) Check the lines for cracks and aging (replace the damaged one) and then change with a fuel filter. Make sure to add fresh diesel, model-matched (filter while fueling) and then turn on the fuel pump manually to let out air for a smooth transfer to injectors.

2. Electrical System Inspection

Concentrate on the battery: Replace it if the battery is damaged or leaking. Clean the terminals that are corroded with baking soda and sandpaper Then apply Vaseline. Charge when voltage (12V/24V standard) is below 80% of its recommended value; replace the older (over three years) or non-recoverable batteries. Verify the wiring of the starter motor as well as ignition circuits and clean the spark plugs and preheaters.

3. Mechanical Component Preparation

Change oil and filters if oil is dark/viscous. Refill with recommended oil, then manually turn the crankshaft 3-5 times to lubricate moving parts—stop if resistance is felt. For the cooling system, drain old fluid, flush, and refill with fresh coolant .

(2) Proper Startup Steps & Tips

1. Engine Preheating

Preheat to boost cylinder temperature and improve fuel atomization. Use preheater plugs (wait 3-5 mins until the light goes off) or external heaters to raise temperature above 5-10℃. Stop if abnormalities occur.

2. First Startup Attempt

Crank briefly to check response. After starting, idle at 600-800 rpm for 5-10 mins. Monitor oil pressure (0.2-0.5MPa), coolant temperature, and exhaust (normal light gray). Shut down immediately if smoke (black/blue/white) or noise appears .

3. Troubleshooting Failed Starts

Wait 30+ seconds between attempts. Check fuel supply (bleed lines if needed), battery voltage, and starter. Adjust valve clearance or test cylinder compression if mechanical issues are suspected.

Part 3. Why Choose a Spring Starter for Long-Term Idle Diesel Engines

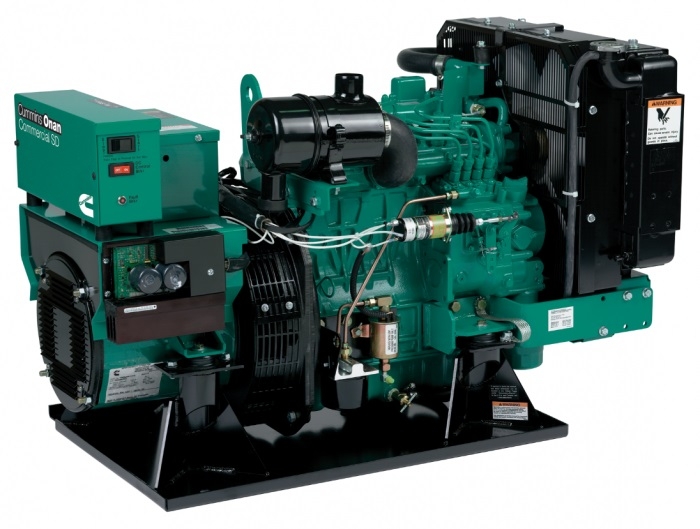

Choosing the right starter is critical for long-term idle diesel engines. Among electric, pneumatic, Cqstart spring starters stand out as ideal due to their unique structure and performance, especially in harsh environments and emergencies.

(1) Working Principle & Features of Spring Starters

They adopt an all-mechanical design, with a high-strength mainspring as the core. Energy is stored in the mainspring manually or electrically; when released, it drives gear sets to rotate the engine crankshaft for startup. Key advantages include: no reliance on external power (avoiding electric starters’ battery dependence, working even with dead batteries or electrical faults), simple structure (fewer parts, no complex circuits, low failure rates, and easy maintenance via regular spring elasticity and gear lubrication checks), and high starting torque (overcoming minor idle-related jams to start the engine smoothly).

(2) Compare Spring Start with Other Starters

VS. Electric Starters

Electric starters are commonly used but are not ideal in idle engines. They depend upon battery power (prone to self-discharge or sulfation upon prolonged idle, which can cause problems with startup) They also have complicated circuits (prone to corrosion, oxidation short circuits, burnout of components) and can experience torque drop due to low voltage batteries. Spring starters can avoid these problems by ensuring stable, battery-free mechanical operation.

VS. Pneumatic Starters

Pneumatic starters make use of compressed air, however they require heavy supporting equipment (compressor air tank, compressor) which adds price and size which makes them ineffective to be used in small engine or restricted space. Air systems that are idle leak easily and maintenance costs can be high. Spring starters are lightweight they do not require additional equipment, and can be used with small generators as well as larger construction equipment.

(3) Adaptability to Special Environments & Emergencies

With aluminum casings, spring starters are resistant to dust, water, and corrosion. They are able to work in dusty, humid or salty conditions. Contrary to electronic starters (battery capacity decreases when temperatures are low) they function with a steady pace between -30 and 50. In the event of an emergency (hospitals or data centers) they can start up immediately with the manual energy storage system, ensuring continuous backup.

Summary

The first step to begin the long-idle diesel engine is to recognize the dangers of idle performing thorough pre-start inspections as well as maintenance, and then selecting the best starter. Among options, spring starters–independent of power, structurally reliable, and highly adaptable to environments–are optimal, especially effective in harsh conditions and emergencies.

By utilizing a sophisticated idle protection strategy and the correct methods for starting motors that are idle can be revived and their life span extended and ensured stability of power to support production and everyday life.

FAQs about Starting Diesel Engine That’s Been Sitting For Years

Q: Engine won’t respond—check first?

A: Inspect electricals: test battery (12V/24V) and clean corroded terminals. If fine, check starter wiring or spring starter gear engagement.

Q: Starts then stalls?

A: Check fuel filter clogging, bleed fuel lines, or injector deposits. Inspect air filter too.

Q: Prevent startup issues during idle?

A: Store with fresh fuel, new oil/filters, disconnected battery, and rust inhibitor. Idle 15–20 mins quarterly.

Q: Spring starter fit all engines?

A: Choose by power/installation specs—fits small/medium (generators) and large (excavators) with kits.

Q: Black/blue smoke after start?

A: Black = poor fuel atomization; blue = oil burning. Stop, fix, then restart.