Diesel air compressors have widespread application in manufacturing, mining, construction, and maritime operations. Nevertheless, a common problem with many users when operating on a day-to-day basis is when they press the start switch, there is no response or the machine is hard to start.

If your diesel compressor won’t start, this article will guide you through step-by-step diagnosis, lead you to a determination of the cause, and introduce an effective and surefire solution, the spring starter. Let’s take a look together!

Part 1. Common Problems of Diesel Air Compressor Won’t Start

A diesel compressor failed startup is not very often caused by a single fault. Most often, it results from a combination of two or three faults working together, and troubleshooting can be problematic. It is thus crucial to learn the different likely trouble areas so the real cause can be identified rapidly. The most common types of causes are:

Problem 1. Electrical System Issues

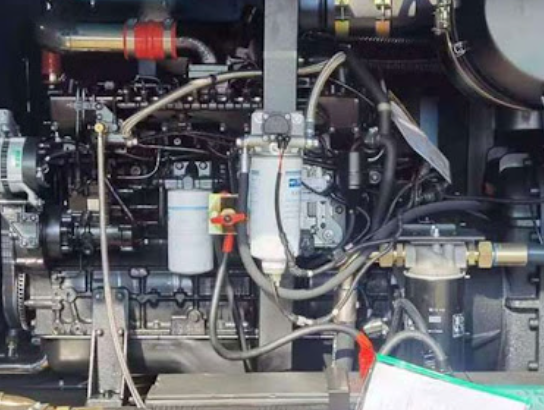

The electrical system is what is needed to start a diesel air compressor. Disruptions in the battery, wiring, or starter motor can prevent the compressor from starting. Some of the problems are:

- Weak or low battery: Deteriorating batteries, batteries left uncharged for a long time, or batteries subjected to extreme temperatures will not provide enough current to energize the starter motor.

- Loose or corroded wiring: Loose, oxidized, or corroded terminals could prevent smooth current flow and make the starter motor free spin or fail to react.

- Starter motor failure: Defective carbon brushes, shorted coils, or faulty relays can freeze the motor and prevent the engine from being started.

Problem 2. Fuel Supply Abnormalities

Fuel system problems directly affect engine ignition. Most are as follows:

- Dirty fuel filters: Diesel will, with time, accumulate impurities, which are sucked into the system and plug the fuel line and reduce fuel supply.

- Air in the fuel system: Worn-out seals or loose fuel lines introduce air into the system, which reduces the injection pressure and leads to incorrect ignition.

- Faulty fuel injection pump: A faulty or worn fuel injection pump cannot provide constant fuel and therefore fails to start the engine.

Problem 3. Mechanical Sticking and Lubrication Issues

Smooth mechanical motion is required for startup. Frozen or insufficiently lubricated internal components can retard startup:

- Long periods of inactivity without maintenance: Rusty bearings, sediment in oil, or insufficient lubrication increase startup resistance and prevent easy engine overhauling.

- Seized internal components: Frozen piston rings, crankshafts, or cylinders will not allow engine rotation and shutdown.

Problem 4. Air System Pressure Problems

Air system issues will also affect starting:

- Malfunctioning unloader valve: If the unloader valve fails to open and discharge back pressure on starting, it causes hard to start, putting extra load on the starter.

- Stuck check valve: If air pressure can’t be discharged, heavy load on the starting motor during startup prevents smooth starting.

Problem 5. Environmental and Operating Factors

Operating practices and environmental conditions also result in startup problems:

- Low temperature conditions: Diesel is more viscous when it is cold, fuel atomization is reduced, and battery capacity is lower, so it is more difficult to start.

- High humidity or dirty environment: Moisture or dirt in the intake system or air filter reduces the combustion rate.

- Improper operation: Failing to perform the correct startup procedure, e.g., not turning on the air or fuel valves, may prevent the compressor from starting.

Problem 6. Control System and Sensor Malfunctions

New diesel air compressors are typically equipped with electronic control systems, and faults here can shut down startup:

- Faulty starter control module: A problematic ECU or starter relay can short out the startup signal.

- Incorrect safety protection devices: Low oil pressure, high-temperature, or overpressure protections can be triggered in error, locking the system.

- Loose or faulty sensor wiring: Faulty speed, pressure, or temperature sensors can make the control system incorrectly sense unsafe conditions, which will prevent startup.

Problem 7. Exhaust and Intake System Failures

Clogging of exhaust or intake systems will increase the engine startup load:

- High exhaust back pressure: Clogged exhaust pipes or stuck check valves contribute to startup resistance.

- Plugged air filters: Reduced intake air can destabilize the fuel-air mixture, decrease combustion efficiency, and make startup difficult.

Problem 8. Diesel Fuel Quality Ailments

Fuel quality is critical to engine ignition:

- Degraded or water-contaminated diesel: Diesel that has deteriorated or absorbed moisture will burn inefficiently, possibly preventing ignition.

- Incorrect fuel type: Low-grade diesel in cold weather may gel, restricting fuel flow and affecting startup.

Part 2. Troubleshooting & Solutions for Air Compressor Problems

From the previous section, we’ve got a list of the most common reasons why diesel air compressors refuse to start. Let’s follow troubleshooting step by step and practical solutions for each category in detail. By following these steps systematically, you can recognize the root cause immediately and take necessary action accordingly.

1.Electrical System

Inspection:

Measure battery voltage with a multimeter. Voltage must be at system requirements (≥12V for 12V systems, ≥24V for 24V systems). Low voltage could be indicative of a weak or discharged battery.

Inspect wiring, terminals, and connectors for looseness, corrosion, oxidation, or damage by visual means. Loose or corroded connections can impede proper current flow.

Operate the starter motor and listen for unusual noise, free spinning, or unusual vibration that could indicate internal motor malfunctions.

Solution

- Clean all battery terminal and connector surfaces. Charge or replace the battery if voltage is low.

- Clean loose wiring and corrosion. Replace cables that are worn out if necessary.

- Replace or refurbish starter motor, brushes, coils, or relays with signs of wear or failure.

2.Fuel Supply

Inspection:

- Check level of fuel and verify that diesel is clean, free from water, and not degraded.

- Bleed air in fuel lines, as it reduces injection pressure and prevents adequate ignition.

- Inspect fuel filters, injection pump, and injectors for blockage, sedimentation, or mechanical damage.

Solution

- Change dirty or plugged fuel filters to ensure free fuel flow.

- Bleed air out of the fuel system to supply adequate injection pressure.

- Clean, repair, or replace injectors and the fuel pump based on needs.

- Always use high-quality, water-free diesel of the proper grade for your operating conditions.

3. Mechanical & Lubrication

Inspection:

- Turn the pulley or crankshaft manually to check for stiffness or internal sticking in pistons, cylinders, or other moving parts.

- Check oil levels, quality, and lubrication of bearings and mechanical components. Insufficient lubrication can cause startup resistance to increase.

Solution

- Grease all moving parts, including bearings, pistons, and shafts, with the proper lubrication.

- For seized or jammed components, utilize professional services for removal and inspection safely.

- Enact routine oil change and lubrication schedule to prevent rusting, corrosion, and mechanical seizure.

4. Air System & Pressure

Inspection:

- Verify that unloader valve and check valves function properly and permit back pressure release upon startup.

- Inspect air filters and exhaust system for restriction or clogging that may impede airflow.

Solution

- Remove clogged air filters or replace them.

- Drain obstructions from the exhaust system and ensure that the valves release pressure in the correct way, reducing the burden on the starter motor.

5. Control System & Sensors

Inspection:

- Check the control panel for error messages or alarm, such as “start failure,” “low voltage,” or “fuel pressure error.”

- Test sensors (speed, pressure, temperature) and relays for proper function.

- Ensure that protection devices are not activated unnecessarily.

Solution

- Reset or replace faulty control modules, relays, or sensors as appropriate.

- Restore any mis-triggered safety protections and allow for normal startup.

6. Environmental & Operational Factors

Inspection:

- Consider ambient temperature, weather, and startup procedures. Low temperatures increase the viscosity of diesel and reduce battery performance.

- Check for dust, humidity, or debris in intake lines and filters.

Solution

- Use preheating equipment or winter-grade diesel fuel when cold weather is met to improve fuel flow and ignition reliability.

- Continue with correct startup procedure, with all fuel and air valves left wide open.

- Maintain filters and intake lines in clean condition to achieve efficient combustion effectiveness.

7. Diesel Fuel Quality

Inspection:

- Check diesel is not deteriorated, water-contaminated, or otherwise not acceptable for use.

- Check fuel grade is adequate to environmental condition, especially in low temperatures.

Solution

- Drain old or dirty fuel and refill with new, high-quality diesel.

- Use the proper diesel grade to prevent gelling or poor atomization.

8. Auxiliary Solutions – Spring Starter

For compressors that frequently experience startup issues or operate in remote/off-grid areas, a spring starter provides a reliable, electricity-free method to rotate the engine. It should be tested regularly to ensure it remains in proper working condition and can deliver immediate startup whenever required.

Tips for Diesel Compressor Troubleshooting:

- Combine systematic troubleshooting with preventive maintenance to minimize future startup failure.

- Embrace a step-by-step diagnostic sequence: External conditions → Control system → Mechanical components → Electrical & fuel systems.

- Keep spare parts and backup alternatives, including a spring starter, handy to allow for rapid response in industrial, marine, or off-grid situations.

Part 3. Spring Starter: Reliable Way to Start Diesel Compressor

If your diesel air compressor fails to start frequently as a result of a dead battery or electrical system failures, a spring starter is a great alternative.

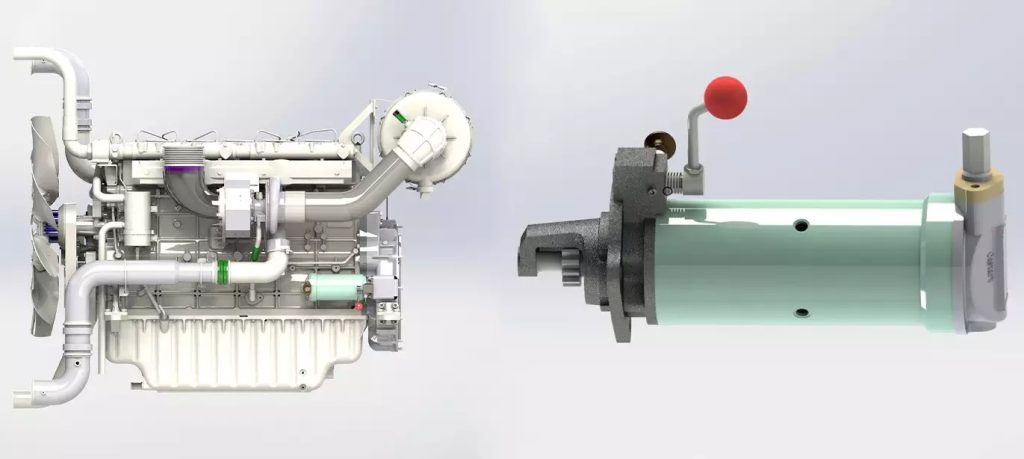

What is a Spring Starter?

A spring starter is a device that turns a diesel engine without any power source, using stored mechanical energy.

The operator simply windes up the spring by rotating the handle. When released, the spring instantly releases its energy, rotating the engine flywheel and firing ignition.

Key Benefits of Spring Starter:

- No battery or electrical system required, completely eliminating the risk of electrical malfunction.

- Reliable in cold, wet, or remote locations, making startup simple.

- Very low maintenance, with only sporadic lubrication needed.

- Multifunctional uses, ideal for diesel air compressors, generators, ship engines, and other machinery.

From mining locations, off-shore platforms, to off-grid building sites, a Spring Starter guarantees your machinery will start when it’s most critical.

Recommended Spring Starter Brand: Cqstart

As a professional spring starter manufacturer, Cqstart offers a wide range of models covering different power levels and specifications of diesel compressors. Their products are extensively tested to ensure efficient startup performance under challenging conditions, thus well suitable for diesel compressor startup systems.

Part 4. Maintenance Tips to Prevent Failure at Diesel Air Compressor Startup

To prevent such recurring issues when your diesel compressor won’t start, keep the following daily and regular maintenance habits:

Regular maintenance of battery and electrical connections

- Monitor the voltage and condition of the battery to ensure that it is capable of providing sufficient starting current.

- Inspect all terminals and cables for looseness, damage, or corrosion and clean them or tighten them as appropriate.

Periodic startup testing

- Start the compressor every month if it has been stationary for a long time.

- This keeps internal components, such as pistons, bearings, and valves, from rusting or seizing.

Periodic replacement of fuel and lubrication components

- Replace fuel filters according to the manufacturer’s specification to ensure free fuel flow.

- Drain engine oil and lubricate moving parts periodically to maintain proper operation.

Check air intake and exhaust systems

- For leaks, blockages, or dirty air filters.

- Verify that check valves and unloader valves operate properly to maintain proper startup pressure.

Test the starting systems periodically

- Test the electric and mechanical (spring starter) starting devices to ensure that they are functioning reliably.

- For spring-start compressors, test the spring mechanism lubrication and the free movement of the winding handle.

- In this way, you will be preventing startup failure to a great extent and extending the service life of your diesel air compressor.

Part 5. When to Upgrade the Compressor Starting System

Replacement or upgrading the starting system should be considered in case your diesel compressor experiences some of the following incidents frequently:

1. Frequent electric starter failure: Frequent discharge battery issues, starter motor failure, or electrical issues indicate the current system may be suspect.

2. Operating in isolated or harsh conditions: Locations with unreliable electricity, extremely cold environments, or offshore platforms may challenge electric starting systems.

3. Emergency or critical application: Applications that require instantaneous or assured startup due to safety or continuity of operations require a fail-safe answer.

In this case, an economy in the long run to invest in a trustworthy mechanical Spring Starter. Benefits are:

- Decreased reliance on electrical equipment and reduced maintenance expenses.

- Increased availability and dependability of your machinery, which will initiate each time when needed.

- Well-suited for hostile environments, i.e., cold weather conditions, off-site locations, or sea environments.

By integrating regular maintenance with the installation of an upgraded starting system if necessary, operators can maximize uptime, protect valuable equipment, and avoid costly downtime due to startup malfunction.

Wrap Up

If a diesel air compressor will not start, never guess at parts replacement or try to force-start the engine for hours on end.

By following a systematic troubleshooting process, you can quickly identify the cause, whether electrical, fuel, or mechanical, and apply the proper solution.

For users who experience regular startup problems, a spring starter offers an effective, electricity-free, and low-maintenance solution.

Want to provide a safer and more efficient start-up solution for your diesel air compressor? Contact Cqstart for a professional Spring Starter solution, and have your equipment ready and start up smoothly!