In construction, agricultural equipment, and generator sets, Perkins engines have been highly reputed for their strength and reliability. However, the engine’s starting system is typically the most critical factor for reliable trouble-free operation.

From cold starting issues to starter wear from repeated use, the right starter selection is critical. This article will provide a comprehensive review starters for Perkins engine, their problems, and selection criteria so that you can make the optimal choice.

Part 1. Perkins Engines Overview

Perkins was established in 1932 and they are now very well known across the globe for their high quality diesel engines. Perkins engines are used throughout the world in various agricultural tools like tractors and harvesters, construction tools like excavators and loaders, as well as generator sets.

Perkins engines are lauded for their great durability and performance. Even with that being said, an engine is only as good as its starter system, and as such an engine needs an efficiently functioning starter system in order to ensure that the engine can start with ease.

The starter not only must initiate the engine rotation but also directly affects fuel efficiency, engine lifespan, and equipment performance. Therefore, choosing a good and suitable starter is a very critical job for all equipment maintenance technicians and engineers.

Part 2. Perkins Engines’ Common Starting Problems

Perkins engines tend to experience diesel engine problems, such as starting issues, which can negatively impact equipment performance and reliability during actual use. These problems are typically caused by environmental factors, engine usage patterns, or the condition of the starter system.

1. Slow Engine Cranking

Causes: Insufficient starter power, low battery state of charge, or old wiring and connections.

Consequences: Longer engine start time, reduced work efficiency, and potential delays in operations.

2. Premature Battery Drain

Causes: Repeated start cycles, extended operation at low temperatures where battery efficiency is low, or poor battery maintenance.

Consequences: Decreased battery life, requiring frequent replacement or additional maintenance, which increases operating costs.

3. Wear or Failure of the Starter

Causes: Extended use, gear slippage, worn brushes, or spring breakage in the starter mechanism.

Consequences: Engine will not start, erratic starting, or unpredictable engine performance.

4. Mechanical Failures

Causes: Slippage of gears, broken or loose springs, or worn components in the starter assembly. Such issues are particularly common in older equipment or engines with high running hours.

Consequences: Catastrophic failure of engine starting or intermittent starting behavior, with potential impacts on equipment reliability and productivity.

Solution:

The key to preventing these issues is selecting a starter that provides stable operation, solid build quality, and proper compatibility with the Perkins engine model. Not only will the installation of the proper starter ensure flawless engine operation, but it will also extend the service life of the starter itself and the engine as well.

Part 3. Types of Perkins Engine Starters

Perkins engines may be equipped with a range of starters to meet specific operating conditions and ambient temperatures. The right starter must be selected to ensure dependable starting of the engine, protect battery life, and promote all-round equipment performance. The principal starter types are outlined in the sections which follow.

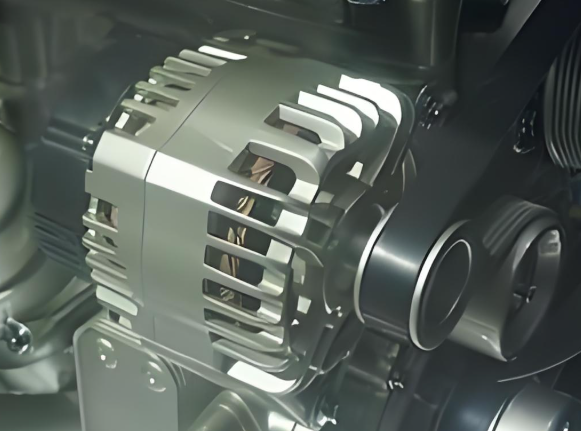

1. Electric Starter

Advantages: Electric starters provide easy and fast engine starting and are ideal for applications involving repetitive or frequent starting. Electric starters allow operators to start engines with ease and are prevalent in contemporary agricultural tractors, construction equipment, and generators.

Limitations: Electric starters put a heavier load on the battery, and their performance can be affected in extremely cold weather. Additionally, maintenance or replacement costs can be relatively higher due to the complexity of electrical components.

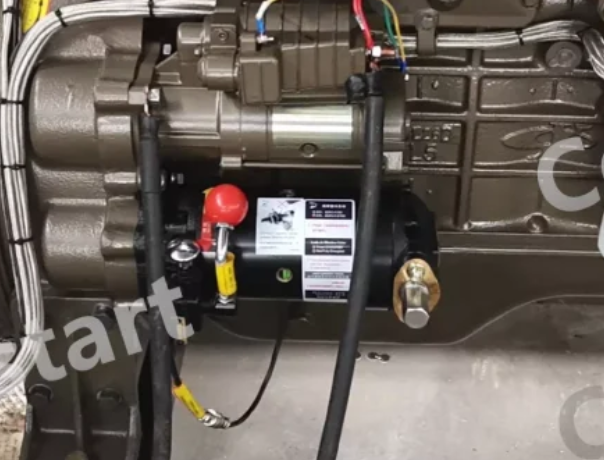

2. Spring Starter

Working Principle: A mechanical spring is employed in a spring starter to store energy, which is released to create the cranking torque. This significantly reduces the reliance on the battery.

Advantages:

- Requires less starting current, thus suitable for weak electrical systems or aged batteries.

- Very reliable in cold weather, where electric starters may struggle.

- Heavy-duty construction with a basic design, which implies minimal maintenance.

Typical Applications: Spring starters are usually used on agricultural equipment, construction equipment, and standby generators where reliable and consistent engine starting is crucial.

3. Other Starter Types

Manual Assist Starters: These are used for emergency starting when the primary starter is unavailable or has failed.

Hydraulic Starters: Suitable for large industrial engines and special equipment requiring high torque and controlled starting.

Each type of starter has its respective advantages and restrictions. The most appropriate starter selection should consider the Perkins engine model, operating conditions, usage frequency, and maintenance ease, to ensure reliability and cost-effectiveness over the long term.

Part 4. How to Choose the Right Starter for Perkins Engines

In selecting a starter for a Perkins engine, there are several key considerations to keep in mind in order to ensure reliable operation and long-term durability.

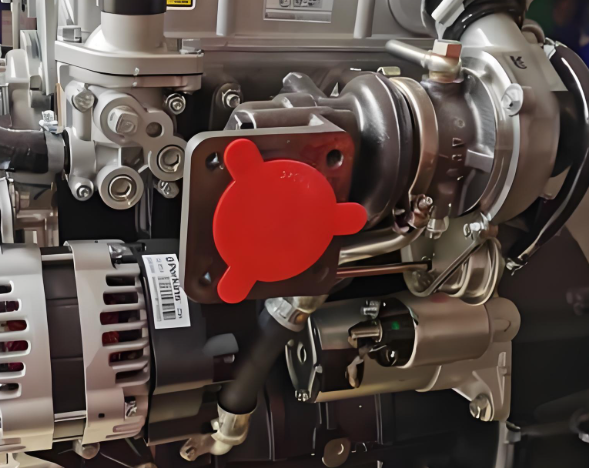

1.Engine Model

Different models of Perkins engines, i.e., the 1103, 1104, and 400 series, need various starter power, size, and torque. Picking a starter that is totally compatible with the specific engine model will guarantee that ineffective starting, unnecessary wear, or even engine damage will not occur. Always cross-reference the starter specifications with the engine manufacturer’s recommendations.

2.Operating Environment

Engine operating conditions influence the selection of the starter. Engines that operate in cold environments, high-humidity environments, or frequent start-stop operations require starters that can consistently operate under stressful conditions. Spring starters, for example, operate excellently under low-temperature conditions due to their low starting current and mechanical simplicity.

3.Maintenance Convenience

Although start automatically (electrically) is faster and more convenient than other methods, it requires more complex circuitry and more attention for ongoing inspection and maintenance than a spring started (mechanically started) system.

Because spring starters (mechanically started) are far easier to install and Inspect/maintain, they are far easier to maintain in the long run eliminating unnecessary downtime and excess maintenance manpower.

4.Performance and Longevity

Having starters from high end manufacturers, and following OEM policy, aids in gaining maximum lifecycle value from the rest of the engine. Benefits of quality starters are not limited to performance enhancement. They also act as a shield for the rest of the equipment from unwanted fractures.

Taking the factors above into account, the starters can be chosen to best cater for maintenance and operation redundancies, ensuring seamless engine function with changing workload.

Part 5. Installation and Maintenance Recommendations

Installation and regular maintenance are crucial to ensure reliable operation and long service life of Perkins engine starters. Correct mounting, proper gear meshing, and sound electrical connections avoid starting troubles, while periodical inspection and timely replacement of worn-out components keep the starter in good condition. The following sections provide guidelines for installation practice and maintenance best practices.

Installation:

Carefully observe the manufacturer’s instructions for installation. Be particularly cautious with gear engagement and spring tension for smooth, efficient performance.

Inspect all electrical connections closely to prevent loose contacts or poor conductivity that will result in starting failures or erratic performance.

Inspect alignment and mounting security to avoid vibration or misalignment that, over a period of time, will result in damage to the starter or engine components.

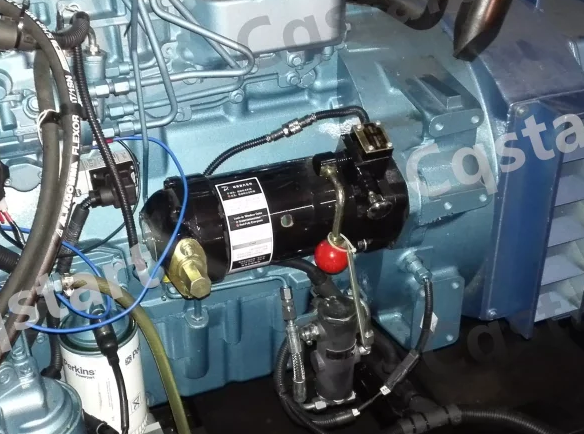

Maintenance:

Occasionally inspect the starter for signs of wear, including spring tension, gear teeth, and electrical connections. Early detection of wear or damage will prevent more expensive engine starting issues.

Replace worn or damaged components with high-quality, OEM-level parts to maintain optimum performance and reliability.

After long periods of no usage, operate the starter manually (wherever it is possible) in order to keep the spring and inner components healthy, preventing stiffness or loss of tension.

Proper installation and periodic maintenance not only significantly extend the life of the starter but also enhance engine starting reliability, reduce downtime, and ensure maximum performance under varying operating conditions.

Part 6. Recommend: Cqstart Engine Starter Solutions

As a professional starter manufacturer, Cqstart is specialized in providing high-quality spring starters for Perkins and other different engine brands.

- Wide Compatibility: Cqstart is compatible with Perkins, such as1104 engines, and other engine brands, such as Cummins, CAT, John Deere, Deutz, and more.

- Durable and Reliable: Made of high-strength materials, our spring starters are made for long-term performance even under severe conditions.

- Easy Installation: Since Cqstart spring starters are simply and effectively designed, they can be replaced or installed easily, reducing equipment downtime.

From agricultural machinery to cold climate operation or high-frequency generator sets, Cqstart spring starters ensure that engines start smoothly, quickly, and reliably every time.

Final Words

The use of the right starter for a Perkins engine not only optimizes engine starting efficiency but also maximizes equipment life and reduces maintenance costs. Spring starters, with their high reliability, durability, and low current requirement, are the preference of the majority of users, while electric starters have a better place in high-frequency applications.

Based on the model of the engine, operating environment, and ease in maintenance, the selection of a professional manufacturer such as Cqstart that offers quality starters is the ideal method to ensure stable and reliable operation in Perkins engines.